CORE_COMPETENCE

Product_Leaders

index_more

index_more_content

info_item01

info_item_content01

info_item02

info_item_content02

info_item03

info_item_content03

info_item04

info_item_content04

NEWS

NEWS

application development in Specialized Sensors for CFR-25JB-52-160R: key technologies and success stories

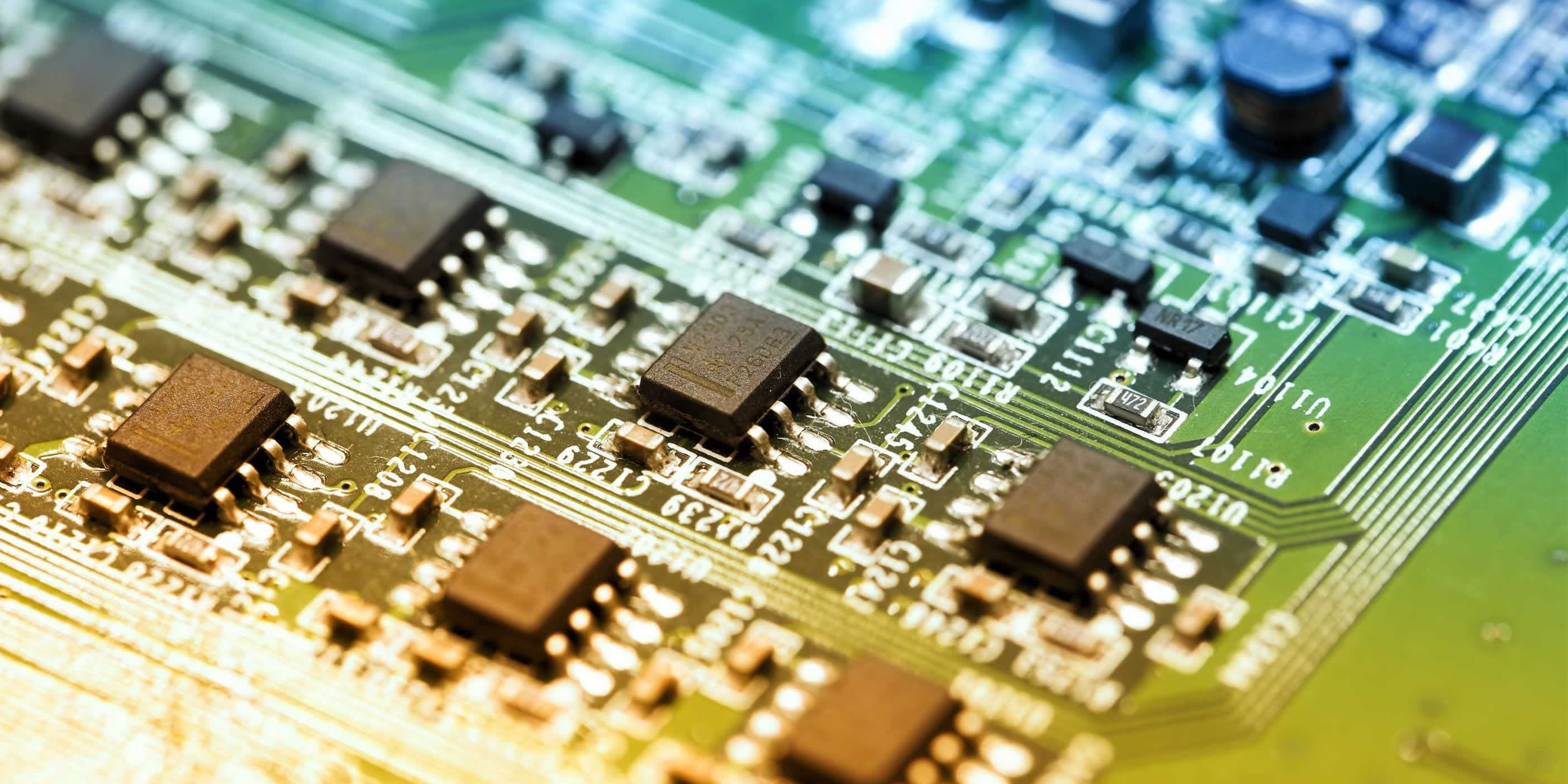

Application Development in Specialized Sensors for CFR-25JB-52-160R: Key Technologies and Success StoriesDeveloping applications for specialized sensors such as the CFR-25JB-52-160R involves leveraging cutting-edge technologies and methodologies tailored to meet specific industry needs. These sensors find applications across various sectors, including aerospace, automotive, and industrial automation. Below, we explore key technologies and notable success stories that highlight the impact of these specialized sensors.

Key Technologies1. Microelectromechanical Systems (MEMS):2. Wireless Sensor Networks (WSN):3. Internet of Things (IoT):4. Data Analytics and Machine Learning:5. Embedded Systems:6. Signal Processing:7. Calibration and Testing Technologies:1. Aerospace Monitoring:2. Automotive Applications:3. Industrial Automation:4. Smart Agriculture:5. Environmental Monitoring: Success Stories ConclusionThe development of applications for specialized sensors like the CFR-25JB-52-160R harnesses a variety of advanced technologies, including MEMS, IoT, and machine learning. The success stories across diverse industries illustrate the transformative impact of these sensors on safety, efficiency, and performance. As technology continues to advance, the potential applications for specialized sensors will expand, driving innovation and enhancing outcomes across numerous fields. The ongoing evolution of sensor technology promises to unlock new possibilities, further integrating these devices into the fabric of modern industry and daily life.

2025-08-18

37