Important Product Categories of Coupling Capacitors

I. Introduction

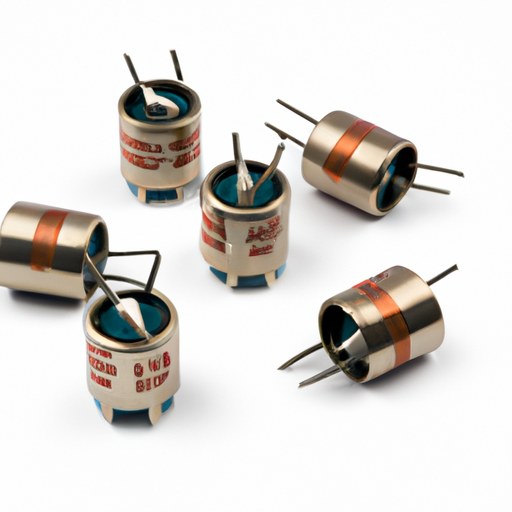

Coupling capacitors are essential components in electronic circuits, serving a critical role in the transmission of signals while blocking direct current (DC). By allowing alternating current (AC) signals to pass through while preventing DC from interfering, coupling capacitors help maintain signal integrity and ensure proper functioning of various electronic devices. This article aims to explore the important product categories of coupling capacitors, their characteristics, applications, and future trends in the industry.

II. Types of Coupling Capacitors

A. Electrolytic Capacitors

**Characteristics:**

Electrolytic capacitors are polarized capacitors that typically offer high capacitance values in a compact size. They are made using an electrolyte, which allows for a larger surface area and, consequently, higher capacitance.

**Applications:**

These capacitors are commonly used in power supply circuits, audio equipment, and coupling applications where high capacitance is required.

**Advantages and Disadvantages:**

The primary advantage of electrolytic capacitors is their high capacitance-to-volume ratio. However, they have a limited voltage rating and can be sensitive to temperature and polarity, which can lead to failure if misused.

B. Ceramic Capacitors

**Characteristics:**

Ceramic capacitors are non-polarized capacitors made from ceramic materials. They are available in various capacitance values and voltage ratings, making them versatile for different applications.

**Applications:**

These capacitors are widely used in high-frequency applications, decoupling, and coupling in audio and RF circuits.

**Advantages and Disadvantages:**

Ceramic capacitors are known for their stability, low equivalent series resistance (ESR), and reliability. However, they can exhibit capacitance changes with voltage (DC bias effect) and temperature, which may limit their use in certain applications.

C. Film Capacitors

**Characteristics:**

Film capacitors are made from thin plastic films as the dielectric material. They are available in various types, including polyester, polypropylene, and polycarbonate.

**Applications:**

These capacitors are often used in audio applications, timing circuits, and coupling applications due to their excellent stability and low distortion.

**Advantages and Disadvantages:**

Film capacitors offer low ESR, high insulation resistance, and good temperature stability. However, they tend to be larger than electrolytic and ceramic capacitors for the same capacitance value, which can be a drawback in space-constrained applications.

D. Tantalum Capacitors

**Characteristics:**

Tantalum capacitors are also polarized and are known for their high capacitance values in small packages. They use tantalum metal as the anode and tantalum pentoxide as the dielectric.

**Applications:**

These capacitors are commonly found in portable electronics, power supply circuits, and coupling applications where size and reliability are critical.

**Advantages and Disadvantages:**

Tantalum capacitors have a stable capacitance and voltage rating, making them suitable for demanding applications. However, they can be more expensive than other types and are sensitive to over-voltage conditions, which can lead to catastrophic failure.

E. Aluminum and Polymer Capacitors

**Characteristics:**

Aluminum capacitors are similar to electrolytic capacitors but use aluminum oxide as the dielectric. Polymer capacitors, on the other hand, use conductive polymer as the electrolyte, offering improved performance.

**Applications:**

Both types are used in power supply circuits, audio applications, and coupling circuits, with polymer capacitors gaining popularity in high-performance applications.

**Advantages and Disadvantages:**

Aluminum capacitors are cost-effective and widely available, while polymer capacitors offer lower ESR and better performance at high frequencies. However, aluminum capacitors can have a shorter lifespan, and polymer capacitors may be more expensive.

III. Key Specifications of Coupling Capacitors

When selecting coupling capacitors, several key specifications must be considered:

A. Capacitance Value

The capacitance value determines how much charge the capacitor can store. It is crucial to select a value that meets the requirements of the specific application.

B. Voltage Rating

The voltage rating indicates the maximum voltage the capacitor can handle without risk of breakdown. It is essential to choose a capacitor with a voltage rating higher than the maximum voltage it will encounter in the circuit.

C. Temperature Coefficient

The temperature coefficient indicates how the capacitance value changes with temperature. A stable temperature coefficient is desirable for applications where temperature variations are expected.

D. Equivalent Series Resistance (ESR)

ESR is a measure of the resistance encountered by the AC signal passing through the capacitor. Lower ESR values are preferred for high-frequency applications to minimize signal loss.

E. Lifetime and Reliability

The expected lifetime and reliability of the capacitor are critical, especially in applications where failure can lead to significant issues. Manufacturers often provide reliability ratings based on testing and usage conditions.

IV. Applications of Coupling Capacitors

Coupling capacitors find applications across various fields, including:

A. Audio Equipment

In audio circuits, coupling capacitors are used to block DC while allowing AC audio signals to pass, ensuring clear sound reproduction.

B. Power Amplifiers

In power amplifiers, coupling capacitors help to couple stages of amplification while preventing DC bias from affecting the subsequent stages.

C. Signal Processing

Coupling capacitors are essential in signal processing circuits, where they help to maintain signal integrity and prevent unwanted DC offsets.

D. Communication Systems

In communication systems, coupling capacitors are used to couple signals between different stages of the circuit, ensuring efficient signal transmission.

E. Power Supply Circuits

In power supply circuits, coupling capacitors help filter out noise and stabilize voltage levels, contributing to the overall performance of the power supply.

V. Selection Criteria for Coupling Capacitors

When selecting coupling capacitors, several criteria should be considered:

A. Application Requirements

Understanding the specific requirements of the application, including capacitance value, voltage rating, and frequency response, is crucial for selecting the right capacitor.

B. Environmental Considerations

Factors such as temperature, humidity, and potential exposure to harsh conditions should be taken into account when choosing capacitors for specific environments.

C. Cost vs. Performance

Balancing cost and performance is essential, as higher-quality capacitors may offer better performance but at a higher price point.

D. Manufacturer Reputation and Quality Assurance

Choosing capacitors from reputable manufacturers with a track record of quality assurance can help ensure reliability and performance in critical applications.

VI. Future Trends in Coupling Capacitors

As technology continues to evolve, several trends are shaping the future of coupling capacitors:

A. Advancements in Materials

Research into new materials is leading to the development of capacitors with improved performance characteristics, such as higher capacitance values and lower ESR.

B. Miniaturization and Integration

The trend towards miniaturization in electronics is driving the development of smaller coupling capacitors that can be integrated into compact devices without sacrificing performance.

C. Sustainability and Eco-Friendly Options

With increasing awareness of environmental issues, manufacturers are exploring sustainable materials and production methods for coupling capacitors, aiming to reduce their ecological footprint.

VII. Conclusion

In conclusion, coupling capacitors play a vital role in electronic circuits, enabling the transmission of AC signals while blocking DC. Understanding the different types of coupling capacitors, their specifications, and applications is essential for selecting the right component for specific needs. As technology advances, the future of coupling capacitors looks promising, with innovations in materials, miniaturization, and sustainability paving the way for enhanced performance and reliability in electronic devices. By staying informed about these trends, engineers and designers can make better choices in their electronic designs, ensuring optimal performance and longevity.