What are the Product Features of Capacitor Banks?

I. Introduction

Capacitor banks are essential components in modern electrical systems, playing a crucial role in enhancing the efficiency and stability of power distribution. A capacitor bank is a group of several capacitors connected in parallel or series to store and release electrical energy. These systems are vital for improving power quality, reducing energy costs, and ensuring the reliable operation of electrical equipment. This article aims to explore the various product features of capacitor banks, including their components, key functionalities, types, performance metrics, and applications across different sectors.

II. Basic Components of Capacitor Banks

A. Capacitors

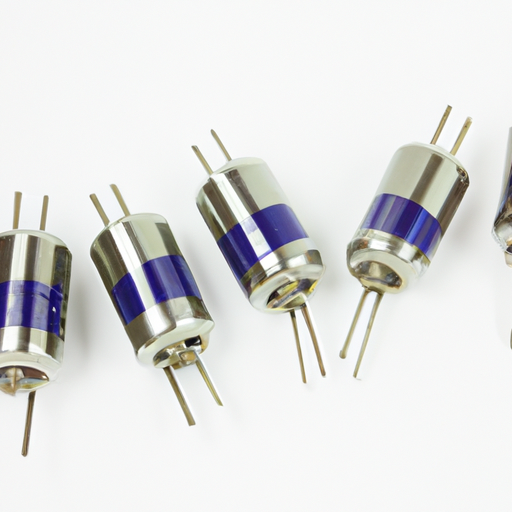

At the heart of any capacitor bank are the capacitors themselves. Various types of capacitors are used in these banks, including:

1. **Film Capacitors**: Known for their stability and reliability, film capacitors are often used in applications requiring high voltage and low losses.

2. **Ceramic Capacitors**: These capacitors are compact and can handle high frequencies, making them suitable for filtering applications.

3. **Electrolytic Capacitors**: Typically used for larger capacitance values, electrolytic capacitors are polarized and are often found in power factor correction applications.

The capacitance values of these capacitors are significant as they determine the amount of electrical energy that can be stored and released. Higher capacitance values allow for greater energy storage, which is essential for applications requiring substantial reactive power compensation.

B. Enclosures and Mounting

The physical design of capacitor banks includes various enclosures and mounting options:

1. **Types of Enclosures**: Capacitor banks can be housed in indoor or outdoor enclosures, depending on the installation environment. Outdoor enclosures are designed to withstand harsh weather conditions, while indoor enclosures provide protection in controlled environments.

2. **Mounting Options**: Capacitor banks can be wall-mounted or floor-mounted, allowing for flexibility in installation based on space availability and application requirements.

C. Protection Devices

To ensure the safe operation of capacitor banks, several protection devices are integrated:

1. **Fuses and Circuit Breakers**: These devices protect the capacitor bank from overcurrent conditions, preventing damage to the capacitors and associated equipment.

2. **Surge Protection Devices**: These devices safeguard against voltage spikes, ensuring the longevity and reliability of the capacitor bank.

III. Key Features of Capacitor Banks

A. Power Factor Correction

One of the primary functions of capacitor banks is power factor correction. The power factor is a measure of how effectively electrical power is being converted into useful work output. A low power factor indicates that a significant portion of the power is reactive, which can lead to increased energy costs and reduced system efficiency. Capacitor banks improve the power factor by supplying reactive power, thus reducing the demand on the electrical supply and enhancing overall system performance.

B. Voltage Regulation

Capacitor banks play a vital role in maintaining voltage stability within electrical systems. By providing reactive power support, they help to stabilize voltage levels, especially during peak demand periods. Improved voltage regulation leads to enhanced performance of electrical equipment, reduced energy losses, and increased operational efficiency.

C. Harmonic Filtering

In electrical systems, harmonics can cause distortion in the voltage and current waveforms, leading to inefficiencies and potential damage to equipment. Capacitor banks can act as harmonic filters, mitigating the effects of harmonics and improving the overall power quality. By reducing harmonic distortion, capacitor banks contribute to the longevity and reliability of electrical systems.

D. Energy Storage

Capacitor banks also serve as energy storage solutions, capable of storing electrical energy for later use. This feature is particularly beneficial in renewable energy systems, such as solar and wind power, where energy generation can be intermittent. By storing excess energy during peak generation times, capacitor banks help to balance supply and demand, enhancing grid stability and performance.

IV. Types of Capacitor Banks

A. Fixed Capacitor Banks

Fixed capacitor banks are designed to provide a constant level of reactive power compensation. They are typically used in applications where the reactive power demand is relatively stable. The advantages of fixed capacitor banks include simplicity and lower initial costs, while their disadvantages include a lack of flexibility in responding to varying load conditions.

B. Automatic Capacitor Banks

Automatic capacitor banks feature control systems that adjust the level of reactive power compensation based on real-time demand. This automation allows for optimal performance and energy savings, as the system can respond dynamically to changes in load conditions. The benefits of automatic systems include improved efficiency and reduced operational costs.

C. Switched Capacitor Banks

Switched capacitor banks utilize switching mechanisms to connect or disconnect capacitors from the circuit as needed. This feature allows for precise control of reactive power compensation, making them suitable for applications with fluctuating loads. The use of switched capacitor banks can lead to significant energy savings and improved power quality.

V. Performance Metrics

A. Efficiency

Efficiency is a critical performance metric for capacitor banks, as it determines how effectively the system converts electrical energy into usable power. Factors affecting efficiency include the quality of the capacitors, the design of the bank, and the operating conditions. High-efficiency capacitor banks contribute to lower energy costs and reduced environmental impact.

B. Reliability

Reliability is paramount in electrical systems, and capacitor banks must be designed to withstand various operating conditions. Features that enhance reliability include robust construction, high-quality components, and effective protection devices. A reliable capacitor bank minimizes downtime and maintenance costs, ensuring continuous operation.

C. Lifespan and Maintenance

The expected lifespan of capacitor banks can vary based on factors such as usage, environmental conditions, and maintenance practices. Regular maintenance is essential to ensure optimal performance and longevity. Best practices include routine inspections, cleaning, and testing of components to identify potential issues before they lead to failure.

VI. Applications of Capacitor Banks

A. Industrial Applications

In industrial settings, capacitor banks are commonly used in manufacturing and processing plants to improve power factor and voltage stability. By reducing energy costs and enhancing the efficiency of power systems, capacitor banks contribute to the overall productivity of industrial operations.

B. Commercial Applications

Capacitor banks play a significant role in commercial buildings and facilities, where they help to manage energy consumption and reduce costs. By improving power quality and reducing demand charges, capacitor banks enable businesses to operate more efficiently and sustainably.

C. Renewable Energy Systems

The integration of capacitor banks in renewable energy systems, such as solar and wind, is becoming increasingly important. These systems help to stabilize the grid by storing excess energy and providing reactive power support, ensuring a reliable and efficient energy supply.

VII. Conclusion

In summary, capacitor banks are vital components in modern electrical systems, offering a range of features that enhance power quality, efficiency, and reliability. From power factor correction to harmonic filtering and energy storage, these systems play a crucial role in various applications, including industrial, commercial, and renewable energy sectors. As technology continues to evolve, the future of capacitor banks looks promising, with advancements aimed at improving performance, efficiency, and integration with smart grid technologies. Understanding the product features of capacitor banks is essential for optimizing their use and maximizing the benefits they provide in today's energy landscape.