What are the Product Features of Electrolytic Capacitors?

I. Introduction

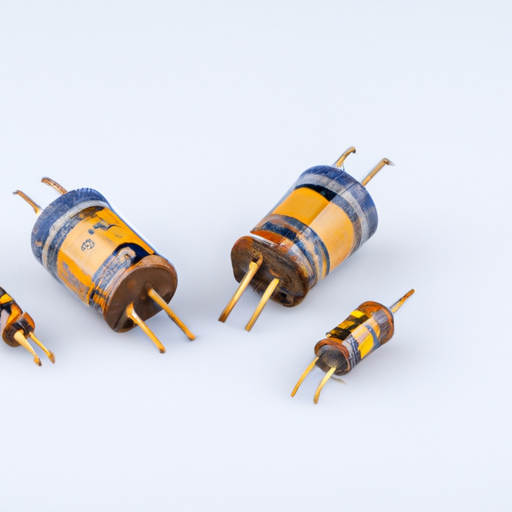

Electrolytic capacitors are essential components in modern electronic circuits, playing a crucial role in energy storage, filtering, and signal processing. These capacitors are distinguished by their ability to achieve high capacitance values in relatively small packages, making them indispensable in various applications, from power supplies to audio equipment. This article aims to explore the product features of electrolytic capacitors, providing insights into their structure, key characteristics, performance, and applications.

II. Basic Structure of Electrolytic Capacitors

A. Components of Electrolytic Capacitors

Electrolytic capacitors consist of three primary components:

1. **Anode**: The anode is typically made of a metal, such as aluminum or tantalum, which is oxidized to form a dielectric layer. This layer is crucial as it allows the capacitor to store electrical energy.

2. **Cathode**: The cathode is usually a conductive layer that interacts with the electrolyte. In aluminum electrolytic capacitors, the cathode is often a liquid or solid electrolyte that facilitates the flow of ions.

3. **Electrolyte**: The electrolyte serves as the medium for ion movement between the anode and cathode. It can be a liquid, gel, or solid, depending on the type of electrolytic capacitor.

B. Types of Electrolytic Capacitors

There are several types of electrolytic capacitors, each with unique properties:

1. **Aluminum Electrolytic Capacitors**: These are the most common type, known for their high capacitance and relatively low cost. They are widely used in power supply circuits and audio applications.

2. **Tantalum Electrolytic Capacitors**: Tantalum capacitors offer higher capacitance values in smaller sizes compared to aluminum capacitors. They are known for their stability and reliability, making them suitable for critical applications.

3. **Niobium Electrolytic Capacitors**: These capacitors are similar to tantalum capacitors but are less expensive and more environmentally friendly. They are gaining popularity in various applications due to their performance characteristics.

III. Key Product Features

A. Capacitance Value

The capacitance value of an electrolytic capacitor indicates its ability to store electrical energy. These capacitors are available in a wide range of capacitance values, typically from a few microfarads (µF) to several thousand microfarads. The choice of capacitance is critical in circuit design, as it affects the performance of filtering, timing, and energy storage applications.

B. Voltage Rating

The voltage rating of an electrolytic capacitor defines the maximum voltage it can withstand without failure. It is essential to select a capacitor with a voltage rating higher than the maximum voltage expected in the circuit. Derating, or using a capacitor at a voltage significantly lower than its rated voltage, is a common practice to enhance reliability and lifespan.

C. Equivalent Series Resistance (ESR)

Equivalent Series Resistance (ESR) is a measure of the internal resistance of a capacitor when it is subjected to an AC signal. A lower ESR is desirable, especially in high-frequency applications, as it minimizes power loss and heat generation. High ESR can lead to reduced efficiency and increased heat, which can affect the capacitor's performance and lifespan.

D. Temperature Range

Electrolytic capacitors have specified operating temperature limits, typically ranging from -40°C to +105°C for aluminum capacitors. The performance of these capacitors can be significantly affected by temperature, with higher temperatures leading to increased leakage current and reduced lifespan. It is crucial to consider the operating environment when selecting a capacitor.

E. Lifetime and Reliability

The lifespan of an electrolytic capacitor is influenced by several factors, including temperature, voltage, and ripple current. Manufacturers often provide a rated lifetime, typically expressed in hours at a specific temperature and voltage. Reliability is paramount in applications where failure can lead to significant consequences, making it essential to choose capacitors from reputable manufacturers.

F. Size and Form Factor

Electrolytic capacitors come in various sizes and form factors, including through-hole and surface-mount options. The physical dimensions of a capacitor can impact circuit design and layout, especially in compact electronic devices. Designers must balance capacitance, voltage rating, and size to meet the requirements of their applications.

G. Leakage Current

Leakage current refers to the small amount of current that flows through a capacitor when it is not in use. This current can be significant in low-power applications, where minimizing power loss is critical. Understanding the leakage current specifications of a capacitor is essential for ensuring efficient circuit operation.

IV. Performance Characteristics

A. Frequency Response

Electrolytic capacitors exhibit different behaviors at various frequencies. Their performance can be characterized by their impedance, which decreases with increasing frequency. This property makes them suitable for applications in filtering and decoupling, where they can effectively smooth out voltage fluctuations and noise.

B. Impedance Characteristics

The impedance of an electrolytic capacitor varies with frequency, impacting its performance in AC applications. At low frequencies, the impedance is higher, while it decreases at higher frequencies. Understanding these characteristics is crucial for selecting the right capacitor for specific applications, such as power supply circuits and audio systems.

C. Ripple Current Handling

Ripple current refers to the AC component of the current flowing through a capacitor in a power supply circuit. Electrolytic capacitors are designed to handle specific ripple current ratings, which are essential for ensuring reliable operation. Exceeding the ripple current rating can lead to overheating and premature failure, making it vital to consider this parameter in circuit design.

V. Applications of Electrolytic Capacitors

Electrolytic capacitors are widely used across various industries and applications:

A. Power Supply Circuits

In power supply circuits, electrolytic capacitors are used for smoothing and filtering, ensuring stable voltage levels and reducing ripple. They are essential in both linear and switching power supplies.

B. Audio Equipment

Electrolytic capacitors are commonly found in audio equipment, where they are used for coupling and decoupling signals. Their ability to handle high capacitance values makes them ideal for applications requiring significant energy storage.

C. Signal Processing

In signal processing applications, electrolytic capacitors are used for filtering and timing circuits. Their frequency response characteristics allow them to effectively manage signal integrity.

D. Consumer Electronics

From televisions to smartphones, electrolytic capacitors are integral to consumer electronics, providing energy storage and filtering capabilities that enhance performance and reliability.

E. Industrial Applications

In industrial settings, electrolytic capacitors are used in motor drives, power inverters, and other equipment where high capacitance and reliability are essential for operation.

VI. Conclusion

In summary, electrolytic capacitors are vital components in electronic circuits, offering a range of features that make them suitable for various applications. Understanding their capacitance values, voltage ratings, ESR, temperature ranges, and other characteristics is crucial for selecting the right capacitor for specific needs. As technology advances, the demand for more efficient and reliable capacitors continues to grow, paving the way for innovations in electrolytic capacitor technology.

VII. References

For further reading and resources on electrolytic capacitors, consider exploring the following:

1. "Capacitors: Technology and Applications" by John Smith

2. "Electrolytic Capacitors: A Comprehensive Guide" by Jane Doe

3. Manufacturer datasheets and application notes from leading capacitor manufacturers.

By understanding the product features of electrolytic capacitors, engineers and designers can make informed decisions that enhance the performance and reliability of their electronic circuits.