What are the Product Characteristics of Low-Voltage Capacitors?

I. Introduction

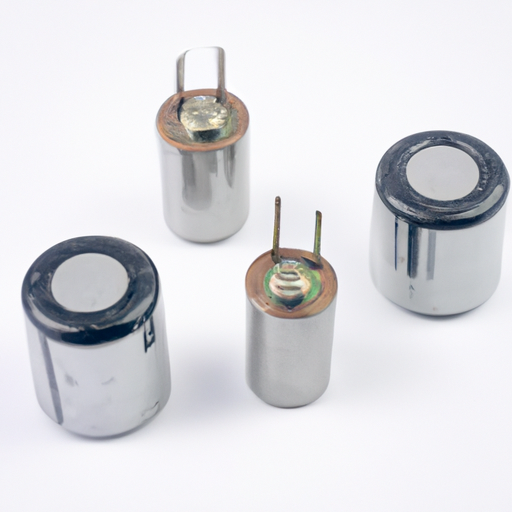

Low-voltage capacitors are essential components in various electrical systems, playing a crucial role in energy storage, filtering, and signal processing. Defined as capacitors designed to operate at voltages typically below 1000 volts, these components are integral to the functionality of many electronic devices and systems. Understanding the product characteristics of low-voltage capacitors is vital for engineers, designers, and technicians who aim to optimize performance and reliability in their applications. This document aims to provide a comprehensive overview of the key characteristics of low-voltage capacitors, their applications, and selection criteria.

II. Overview of Capacitors

A. Basic Function of Capacitors

Capacitors are passive electronic components that store and release electrical energy. They consist of two conductive plates separated by an insulating material known as a dielectric. When a voltage is applied across the plates, an electric field is created, allowing the capacitor to store energy. This stored energy can be released when needed, making capacitors essential for various applications, including smoothing out voltage fluctuations, filtering signals, and providing energy storage in power systems.

B. Types of Capacitors

There are several types of capacitors, each with unique characteristics and applications:

1. **Electrolytic Capacitors**: Known for their high capacitance values, these capacitors are polarized and typically used in power supply circuits.

2. **Ceramic Capacitors**: These non-polarized capacitors are widely used in high-frequency applications due to their stability and low ESR.

3. **Film Capacitors**: Made from thin plastic films, these capacitors are known for their reliability and are often used in audio and power applications.

4. **Tantalum Capacitors**: These capacitors offer high capacitance in a small size and are commonly used in portable electronics.

C. Role of Low-Voltage Capacitors in Circuits

Low-voltage capacitors are used in various circuits to perform functions such as energy storage, voltage regulation, and signal coupling. They help maintain stable voltage levels, filter out noise, and improve the overall efficiency of electronic systems.

III. Key Product Characteristics of Low-Voltage Capacitors

A. Voltage Rating

1. Definition and Importance

The voltage rating of a capacitor indicates the maximum voltage that can be applied across its terminals without risking failure. Exceeding this rating can lead to dielectric breakdown, resulting in catastrophic failure.

2. Common Voltage Ratings for Low-Voltage Capacitors

Low-voltage capacitors typically have voltage ratings ranging from 6.3V to 1000V. Common ratings include 16V, 25V, 35V, and 50V, depending on the application requirements.

B. Capacitance Value

1. Definition and Measurement Units

Capacitance is the ability of a capacitor to store electrical charge, measured in farads (F). Most low-voltage capacitors are rated in microfarads (µF) or picofarads (pF).

2. Range of Capacitance Values in Low-Voltage Capacitors

Low-voltage capacitors can have capacitance values ranging from a few picofarads to several thousand microfarads, depending on the type and application.

C. Tolerance

1. Definition and Importance

Tolerance refers to the allowable deviation from the nominal capacitance value. It is crucial for ensuring that capacitors perform as expected in a circuit.

2. Common Tolerance Levels

Common tolerance levels for low-voltage capacitors include ±5%, ±10%, and ±20%, with tighter tolerances available for specific applications.

D. Temperature Coefficient

1. Definition and Impact on Performance

The temperature coefficient indicates how a capacitor's capacitance changes with temperature. It is essential for maintaining performance in varying environmental conditions.

2. Types of Temperature Coefficients

Common types of temperature coefficients include X7R, C0G, and Y5V, each with different stability characteristics over temperature ranges.

E. Equivalent Series Resistance (ESR)

1. Definition and Importance

ESR is the internal resistance of a capacitor that affects its efficiency and performance, particularly in high-frequency applications.

2. Impact on Performance and Efficiency

A lower ESR results in better performance, reduced heat generation, and improved efficiency, making it a critical characteristic for power supply applications.

F. Lifetime and Reliability

1. Factors Affecting Lifetime

The lifetime of a low-voltage capacitor can be influenced by factors such as temperature, voltage stress, and ripple current.

2. Typical Lifespan of Low-Voltage Capacitors

Depending on the type and operating conditions, low-voltage capacitors can have lifespans ranging from a few thousand hours to over 10,000 hours.

G. Size and Form Factor

1. Importance of Size in Design

The physical size of a capacitor can significantly impact the design of electronic circuits, especially in compact devices.

2. Common Form Factors for Low-Voltage Capacitors

Low-voltage capacitors come in various form factors, including surface mount, through-hole, and axial lead types, allowing for flexibility in design.

IV. Applications of Low-Voltage Capacitors

Low-voltage capacitors are used in a wide range of applications, including:

A. Consumer Electronics

In devices such as smartphones, tablets, and televisions, low-voltage capacitors help stabilize power supplies and filter signals.

B. Industrial Equipment

Low-voltage capacitors are used in motor drives, power supplies, and control systems to enhance performance and reliability.

C. Automotive Applications

In modern vehicles, low-voltage capacitors are essential for power management, audio systems, and electronic control units.

D. Renewable Energy Systems

Low-voltage capacitors play a vital role in energy storage and management in solar inverters and wind turbine systems.

E. Telecommunications

In telecommunications equipment, low-voltage capacitors are used for signal coupling, decoupling, and filtering to ensure clear communication.

V. Selection Criteria for Low-Voltage Capacitors

When selecting low-voltage capacitors, several criteria should be considered:

A. Application Requirements

Understanding the specific requirements of the application, including voltage, capacitance, and tolerance, is crucial for selecting the right capacitor.

B. Environmental Considerations

Factors such as temperature, humidity, and exposure to chemicals can affect capacitor performance and longevity.

C. Cost vs. Performance Trade-offs

Balancing cost and performance is essential, as higher-quality capacitors may offer better reliability but at a higher price.

D. Manufacturer Reputation and Standards

Choosing capacitors from reputable manufacturers that adhere to industry standards ensures quality and reliability.

VI. Conclusion

In summary, low-voltage capacitors are critical components in various electronic systems, with key characteristics such as voltage rating, capacitance value, tolerance, temperature coefficient, ESR, lifetime, and size playing significant roles in their performance. Understanding these characteristics is essential for effective use and selection in diverse applications. As technology advances, trends such as miniaturization, increased efficiency, and enhanced reliability will continue to shape the future of low-voltage capacitor technology.

VII. References

1. Academic Journals on Capacitor Technology

2. Industry Standards for Capacitors (IEC, ANSI)

3. Manufacturer Specifications and Data Sheets

4. Technical Guides and White Papers on Capacitor Applications

This comprehensive overview of low-voltage capacitors provides valuable insights for engineers and designers, ensuring they can make informed decisions in their projects.