Important Product Categories for Capacitor Charging

I. Introduction

Capacitor charging is a fundamental process in electrical engineering that involves storing electrical energy in capacitors for later use. Capacitors play a crucial role in various applications, from power supply systems to electronic devices, making their charging mechanisms equally important. This article will explore the essential product categories involved in capacitor charging, providing insights into their functionalities, applications, and emerging technologies.

II. Understanding Capacitors

A. What is a Capacitor?

A capacitor is an electronic component that stores electrical energy in an electric field. It consists of two conductive plates separated by an insulating material known as a dielectric. When voltage is applied across the plates, an electric field is created, allowing the capacitor to store energy.

1. Basic Functionality

The primary function of a capacitor is to store and release electrical energy. When connected to a power source, it charges up to the voltage of that source. When disconnected, it can discharge its stored energy to power a circuit or device.

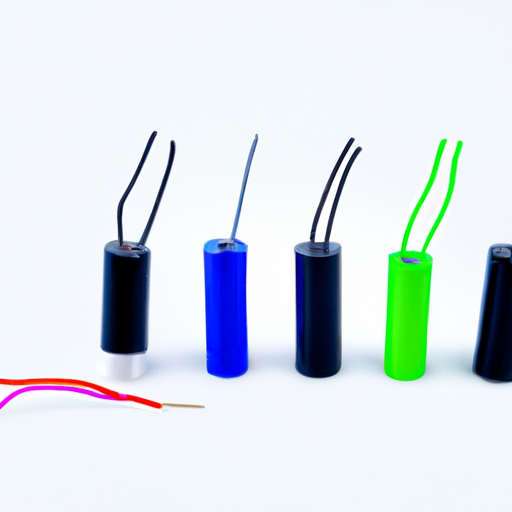

2. Types of Capacitors

Capacitors come in various types, including ceramic, electrolytic, tantalum, and film capacitors, each with unique characteristics suited for different applications.

B. Role of Capacitors in Electrical Circuits

Capacitors serve multiple purposes in electrical circuits:

1. Energy Storage

Capacitors are widely used for energy storage in power supply systems, allowing for quick bursts of energy when needed.

2. Filtering and Smoothing

In power supply circuits, capacitors help filter out noise and smooth voltage fluctuations, ensuring a stable output.

3. Timing Applications

Capacitors are also used in timing circuits, where they charge and discharge at specific rates to control timing functions.

III. Key Product Categories for Capacitor Charging

A. Capacitor Chargers

1. Definition and Functionality

Capacitor chargers are devices specifically designed to charge capacitors safely and efficiently. They control the voltage and current supplied to the capacitor, ensuring it charges to the desired level without damage.

2. Types of Capacitor Chargers

Manual Chargers: These require the user to monitor the charging process and disconnect the charger once the capacitor is fully charged.

Automatic Chargers: These chargers automatically stop charging once the capacitor reaches a predetermined voltage, reducing the risk of overcharging.

Smart Chargers: Equipped with advanced features, smart chargers can communicate with other devices, adjust charging parameters in real-time, and provide diagnostic information.

3. Applications and Use Cases

Capacitor chargers are used in various applications, including power electronics, automotive systems, and renewable energy systems, where reliable and efficient charging is essential.

B. Power Supplies

1. Role of Power Supplies in Capacitor Charging

Power supplies provide the necessary voltage and current to charge capacitors. The choice of power supply can significantly impact the charging speed and efficiency.

2. Types of Power Supplies

Linear Power Supplies: These provide a stable output voltage but can be less efficient and generate more heat compared to switching supplies.

Switching Power Supplies: More efficient than linear supplies, switching power supplies can adjust their output based on load requirements, making them ideal for capacitor charging applications.

3. Selection Criteria for Power Supplies

When selecting a power supply for capacitor charging, consider factors such as output voltage, current rating, efficiency, and thermal performance.

C. Resistors and Inductors

1. Importance in Charging Circuits

Resistors and inductors are critical components in capacitor charging circuits, influencing the charging time and efficiency.

2. Types of Resistors and Inductors

Resistors: Used to limit current and control the charging rate of capacitors.

Inductors: Can be used to smooth out current changes, providing a more stable charging process.

3. How They Affect Charging Time and Efficiency

The values of resistors and inductors in a circuit can significantly affect how quickly a capacitor charges and how efficiently it does so. Proper selection is crucial for optimal performance.

D. Voltage Regulators

1. Purpose and Functionality

Voltage regulators maintain a constant output voltage, ensuring that capacitors are charged under stable conditions.

2. Types of Voltage Regulators

Linear Regulators: Simple and effective, these regulators provide a steady output voltage but can be less efficient.

Switching Regulators: More complex but highly efficient, switching regulators can handle varying loads and maintain stable voltage levels.

3. Importance in Maintaining Stable Charging Conditions

Stable voltage is essential for safe and effective capacitor charging. Voltage regulators help prevent overvoltage conditions that could damage capacitors.

E. Circuit Protection Devices

1. Need for Protection in Charging Circuits

Charging circuits can be susceptible to faults and surges, making circuit protection devices essential for safety and reliability.

2. Types of Protection Devices

Fuses: Provide overcurrent protection by breaking the circuit when current exceeds a certain level.

Circuit Breakers: Automatically interrupt the circuit in case of overload or short circuit conditions.

Surge Protectors: Protect against voltage spikes that can damage capacitors and other components.

3. How They Enhance Safety and Reliability

By incorporating circuit protection devices, the risk of damage to capacitors and other components is significantly reduced, enhancing the overall reliability of the charging system.

F. Testing and Measurement Equipment

1. Importance of Testing in Capacitor Charging

Testing and measurement equipment are vital for ensuring that capacitors are charged correctly and functioning as intended.

2. Types of Testing Equipment

Multimeters: Used to measure voltage, current, and resistance in charging circuits.

Oscilloscopes: Provide visual representations of voltage and current waveforms, helping diagnose issues in charging circuits.

LCR Meters: Measure inductance (L), capacitance (C), and resistance (R), providing insights into capacitor health and performance.

3. Role in Ensuring Proper Functionality

Regular testing helps identify potential issues before they lead to failures, ensuring that capacitor charging systems operate efficiently and safely.

IV. Emerging Technologies in Capacitor Charging

A. Advancements in Charging Techniques

1. Fast Charging Technologies

Recent advancements in fast charging technologies allow capacitors to charge more quickly, improving the efficiency of power systems and electronic devices.

2. Wireless Charging for Capacitors

Wireless charging technologies are emerging, enabling capacitors to be charged without direct electrical connections, enhancing convenience and flexibility in various applications.

B. Smart Charging Solutions

1. Integration with IoT

Smart charging solutions are increasingly integrating with the Internet of Things (IoT), allowing for remote monitoring and control of charging processes.

2. Benefits of Smart Charging Systems

These systems can optimize charging times, reduce energy consumption, and provide real-time diagnostics, improving overall system performance.

V. Considerations for Selecting Products

A. Application Requirements

When selecting products for capacitor charging, it is essential to consider the specific requirements of the application, including voltage, current, and energy storage needs.

B. Compatibility with Existing Systems

Ensure that the selected products are compatible with existing systems to avoid integration issues and maximize performance.

C. Cost vs. Performance Trade-offs

Evaluate the trade-offs between cost and performance, as higher-quality products may offer better efficiency and reliability but at a higher price.

D. Manufacturer Reputation and Support

Choose products from reputable manufacturers that offer reliable support and warranty options, ensuring peace of mind in case of issues.

VI. Conclusion

In summary, understanding the important product categories for capacitor charging is essential for anyone involved in electrical engineering or related fields. From capacitor chargers and power supplies to circuit protection devices and testing equipment, each component plays a vital role in ensuring efficient and safe capacitor charging. As technology continues to evolve, emerging solutions such as fast charging and smart systems will further enhance the capabilities of capacitor charging, paving the way for more efficient and reliable electrical systems.

VII. References

A. Suggested Reading and Resources

- "Capacitors: Principles and Applications" by John Smith

- "Power Supply Design" by Jane Doe

B. Industry Standards and Guidelines

- IEEE Standards for Capacitor Charging

- IEC Guidelines for Electrical Safety in Charging Systems

By understanding these categories and their functionalities, engineers and technicians can make informed decisions that enhance the performance and reliability of their capacitor charging systems.