What is the Purchase Price of the Latest Chip Resistors?

I. Introduction

In the world of electronics, chip resistors play a crucial role in ensuring the proper functioning of devices. These tiny components, often overlooked, are essential for controlling current flow and voltage levels in various applications. As technology advances, the demand for high-quality chip resistors continues to grow, leading to fluctuations in their purchase prices. This article aims to explore the current market prices of the latest chip resistors, the factors influencing these prices, and future trends that may affect the electronics industry.

II. Understanding Chip Resistors

A. What are Chip Resistors?

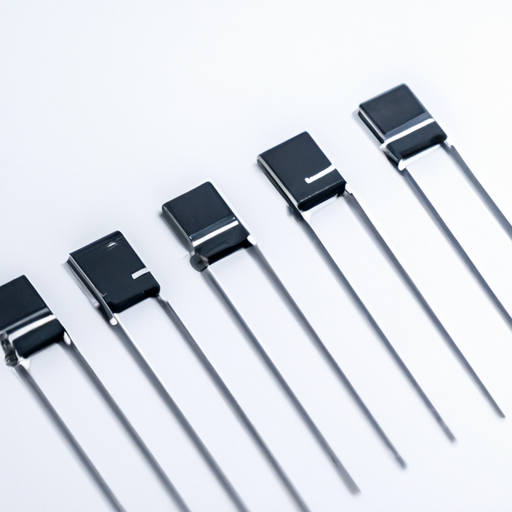

Chip resistors are miniature electronic components that provide resistance in a circuit. They are typically made from a combination of conductive materials and substrates, allowing them to be compact and efficient. The construction of chip resistors involves layering materials to create a resistive element, which is then encapsulated to protect it from environmental factors.

1. Description and Construction

Chip resistors are usually rectangular in shape and come in various sizes, measured in millimeters. Their small form factor makes them ideal for surface-mount technology (SMT), allowing for automated assembly in electronic devices. The construction process involves depositing a resistive film onto a ceramic substrate, followed by cutting the film to achieve the desired resistance value.

2. Types of Chip Resistors

There are several types of chip resistors, each with unique characteristics:

Thick Film Resistors: These are the most common type, made by printing a thick layer of resistive material onto a substrate. They are cost-effective and suitable for a wide range of applications.

Thin Film Resistors: These resistors are made by depositing a thin layer of resistive material, offering higher precision and stability. They are often used in high-end applications where accuracy is critical.

Wirewound Resistors: These consist of a wire wound around a core, providing high power ratings and excellent performance in specific applications.

B. Applications of Chip Resistors

Chip resistors are used in various industries, including:

1. Consumer Electronics

From smartphones to laptops, chip resistors are integral to consumer electronics, ensuring devices operate efficiently and reliably.

2. Automotive Industry

In modern vehicles, chip resistors are used in various systems, including engine control units, safety features, and infotainment systems, contributing to overall vehicle performance.

3. Industrial Applications

Chip resistors are essential in industrial equipment, where they help manage power and signal processing in machinery and control systems.

4. Telecommunications

In telecommunications, chip resistors are used in devices such as routers and switches, ensuring stable signal transmission and reception.

III. Factors Influencing the Price of Chip Resistors

Several factors contribute to the pricing of chip resistors, making it essential for buyers to understand these dynamics.

A. Material Composition

The materials used in chip resistors significantly impact their cost. High-quality conductive materials and substrates can increase production costs, which may be reflected in the final price.

1. Conductive Materials Used

Common conductive materials include metal oxides and carbon, with variations in quality affecting performance and price.

2. Substrate Materials

Ceramic substrates are widely used due to their stability and durability, but alternative materials may offer cost savings at the expense of performance.

B. Manufacturing Processes

The methods used to manufacture chip resistors also influence their pricing.

1. Automation and Technology in Production

Advanced manufacturing technologies can reduce production costs and improve efficiency, leading to lower prices for consumers.

2. Scale of Production

Mass production often results in economies of scale, allowing manufacturers to offer competitive pricing. Conversely, low-volume production can lead to higher costs.

C. Specifications and Performance Characteristics

The specific characteristics of chip resistors, such as resistance values, tolerance levels, and power ratings, can also affect their pricing.

1. Resistance Values

Higher resistance values may require more complex manufacturing processes, impacting the overall cost.

2. Tolerance Levels

Resistors with tighter tolerance levels (greater accuracy) typically command higher prices due to the precision required in their production.

3. Power Ratings

Chip resistors designed to handle higher power levels are often more expensive due to the materials and construction techniques involved.

D. Market Demand and Supply Dynamics

The electronics market is subject to fluctuations in demand and supply, which can significantly impact chip resistor prices.

1. Trends in the Electronics Market

As technology evolves, the demand for specific types of chip resistors may increase, leading to price changes.

2. Impact of Global Supply Chain Issues

Recent global events, such as the COVID-19 pandemic, have disrupted supply chains, causing shortages and price increases for many electronic components, including chip resistors.

IV. Current Market Prices of Chip Resistors

A. Overview of Pricing Trends

The pricing of chip resistors has seen notable changes over the years, influenced by various market factors.

1. Historical Price Changes

Historically, chip resistor prices have fluctuated based on material costs, manufacturing advancements, and market demand.

2. Recent Price Fluctuations

In recent months, prices have experienced volatility due to supply chain disruptions and increased demand for electronic devices.

B. Price Ranges for Different Types of Chip Resistors

The price of chip resistors varies widely based on type and specifications.

1. Low-End vs. High-End Resistors

Low-end chip resistors can be found for as little as a few cents each, while high-end models may cost several dollars, depending on their specifications.

2. Comparison of Prices Across Manufacturers

Prices can vary significantly between manufacturers, with some offering premium products at a higher cost due to brand reputation and quality assurance.

C. Case Studies of Specific Chip Resistors

1. Popular Models and Their Prices

For example, a standard 0603 thick film resistor may cost around $0.05, while a high-precision thin film resistor of the same size could be priced at $0.50 or more.

2. Analysis of Price-Performance Ratios

When evaluating chip resistors, it is essential to consider the price-performance ratio, ensuring that the chosen component meets the required specifications without overspending.

V. Where to Purchase Chip Resistors

A. Online Marketplaces

The internet has made it easier than ever to purchase chip resistors.

1. Major Distributors

Websites like Digi-Key, Mouser, and Newark offer extensive catalogs of chip resistors, allowing buyers to compare prices and specifications easily.

2. Manufacturer Websites

Purchasing directly from manufacturers can sometimes yield better prices, especially for bulk orders.

B. Local Electronic Component Suppliers

Local suppliers can provide immediate access to chip resistors, which is beneficial for urgent projects.

C. Bulk Purchasing Options and Their Advantages

Buying in bulk can lead to significant cost savings, making it an attractive option for businesses and hobbyists alike.

D. Considerations for Purchasing

When purchasing chip resistors, buyers should consider factors such as minimum order quantities, shipping costs, and lead times to ensure a smooth procurement process.

VI. Future Trends in Chip Resistor Pricing

A. Technological Advancements and Their Impact on Pricing

As manufacturing technologies continue to evolve, we can expect improvements in efficiency and reductions in production costs, potentially leading to lower prices for consumers.

B. Predictions for Market Demand

With the ongoing growth of the electronics industry, demand for chip resistors is likely to remain strong, which may keep prices stable or even increase them in the short term.

C. Potential Effects of Geopolitical Factors on Supply Chains

Geopolitical tensions and trade policies can impact the availability and pricing of chip resistors, making it essential for buyers to stay informed about global events.

VII. Conclusion

In summary, chip resistors are vital components in modern electronics, and their purchase prices are influenced by various factors, including material composition, manufacturing processes, and market dynamics. Understanding these elements can help buyers make informed decisions when purchasing chip resistors. As the electronics industry continues to evolve, staying informed about pricing trends will be crucial for both manufacturers and consumers alike.

VIII. References

For further reading, consider exploring industry reports, market analysis documents, and manufacturer specifications and datasheets to gain deeper insights into chip resistors and their pricing dynamics.