What Kind of Product Are Fixed Resistors?

I. Introduction

In the world of electronics, components are the building blocks that make up circuits and devices. Among these components, fixed resistors play a crucial role. A fixed resistor is a passive electronic component that provides a specific, unchanging resistance to the flow of electric current. This article will delve into the definition, characteristics, types, applications, and selection criteria of fixed resistors, highlighting their importance in modern electronics.

II. Understanding Resistors

A. What is a Resistor?

At its core, a resistor is a device that resists the flow of electric current. It is designed to limit the amount of current that can pass through a circuit, thereby controlling voltage levels and protecting sensitive components. Resistors are essential for managing the behavior of electrical circuits, ensuring that they function correctly and safely.

B. Types of Resistors

Resistors can be broadly categorized into two main types: fixed and variable.

1. **Fixed Resistors** maintain a constant resistance value regardless of the voltage or current passing through them.

2. **Variable Resistors**, such as potentiometers, allow users to adjust the resistance value as needed.

Additionally, there are specialty resistors designed for specific applications, but fixed resistors are the most commonly used in everyday electronics.

III. Characteristics of Fixed Resistors

A. Definition and Functionality

Fixed resistors are characterized by their constant resistance value, which is determined during manufacturing. This stability makes them ideal for applications where precise resistance is required. They are used in various circuits to limit current, divide voltages, and protect components from excessive current.

B. Common Specifications

When selecting a fixed resistor, several specifications are important to consider:

1. **Resistance Value**: Measured in ohms (Ω), this value indicates how much the resistor opposes the flow of current.

2. **Power Rating**: This specification, measured in watts (W), indicates the maximum amount of power the resistor can dissipate without overheating.

3. **Tolerance**: This percentage indicates how much the actual resistance can vary from the stated value. A lower tolerance means higher precision.

4. **Temperature Coefficient**: This specification indicates how much the resistance value changes with temperature, which is crucial for applications in varying environmental conditions.

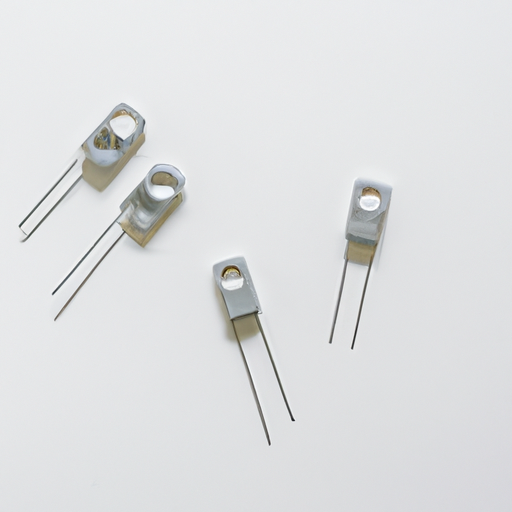

IV. Types of Fixed Resistors

Fixed resistors come in various types, each with unique characteristics and applications.

A. Carbon Composition Resistors

These resistors are made from a mixture of carbon and a binding material. They are known for their low cost and ability to withstand high energy pulses. However, they have a higher tolerance and lower stability compared to other types, making them less suitable for precision applications.

B. Carbon Film Resistors

Manufactured by depositing a thin layer of carbon on a ceramic substrate, carbon film resistors offer better stability and lower noise than carbon composition resistors. They are widely used in consumer electronics due to their good performance and affordability.

C. Metal Film Resistors

These resistors are made by depositing a thin layer of metal onto a ceramic substrate. They are known for their precision, stability, and low temperature coefficient, making them ideal for applications requiring high accuracy, such as in measurement devices.

D. Wirewound Resistors

Constructed by winding a metal wire around a ceramic or fiberglass core, wirewound resistors can handle high power levels and are often used in power applications. However, they can be bulkier and more expensive than other types.

E. Other Types

1. **Thin Film Resistors**: These resistors are made by depositing a very thin layer of resistive material on a substrate. They offer high precision and stability, making them suitable for high-end applications.

2. **Thick Film Resistors**: These are made by printing a thick layer of resistive material onto a substrate. They are commonly used in applications where cost is a concern but some level of precision is still required.

V. Applications of Fixed Resistors

Fixed resistors are ubiquitous in various fields, serving critical functions in numerous applications.

A. In Consumer Electronics

In consumer electronics, fixed resistors are found in devices such as audio equipment and home appliances. They help manage signal levels, protect circuits, and ensure devices operate within safe parameters.

B. In Industrial Applications

In industrial settings, fixed resistors are used in automation systems and power distribution networks. They help regulate current flow, protect sensitive equipment, and ensure reliable operation in demanding environments.

C. In Automotive Electronics

Fixed resistors play a vital role in automotive electronics, including engine control units and safety systems. They help manage sensor signals, control actuators, and ensure the reliability of critical systems.

D. In Telecommunications

In telecommunications, fixed resistors are essential for signal processing and network equipment. They help maintain signal integrity, manage power levels, and protect sensitive components from voltage spikes.

VI. Selecting the Right Fixed Resistor

Choosing the right fixed resistor for a specific application requires careful consideration of several factors.

A. Factors to Consider

1. **Resistance Value**: Ensure the resistor's value matches the requirements of your circuit.

2. **Power Rating**: Select a resistor with a power rating that exceeds the expected power dissipation to prevent overheating.

3. **Tolerance and Temperature Coefficient**: Consider the precision required for your application and choose a resistor with an appropriate tolerance and temperature coefficient.

B. Common Mistakes to Avoid

1. **Underestimating Power Requirements**: Failing to account for the power dissipation can lead to resistor failure and circuit damage.

2. **Ignoring Tolerance Levels**: Choosing a resistor with a tolerance that is too high for your application can result in inaccurate circuit performance.

VII. Conclusion

Fixed resistors are fundamental components in the world of electronics, providing essential functionality across a wide range of applications. Their ability to maintain a constant resistance value makes them invaluable in ensuring the reliability and performance of electronic devices. As technology continues to evolve, advancements in resistor technology will likely lead to even more precise and efficient components, further solidifying the role of fixed resistors in modern electronics.

VIII. References

A. Suggested Reading

- "The Art of Electronics" by Paul Horowitz and Winfield Hill

- "Electronic Principles" by Albert Malvino and David Bates

B. Industry Standards and Guidelines

- IEC 60115: Resistors for use in electronic equipment

- EIA-198: Standard for Fixed Resistors

C. Online Resources for Further Learning

- Electronics tutorials on websites like All About Circuits and Electronics-Tutorials.ws

- Manufacturer datasheets for specific resistor types and specifications

By understanding the characteristics, types, and applications of fixed resistors, engineers and hobbyists alike can make informed decisions when designing and building electronic circuits.