What are the Popular Capacitor Product Models?

I. Introduction

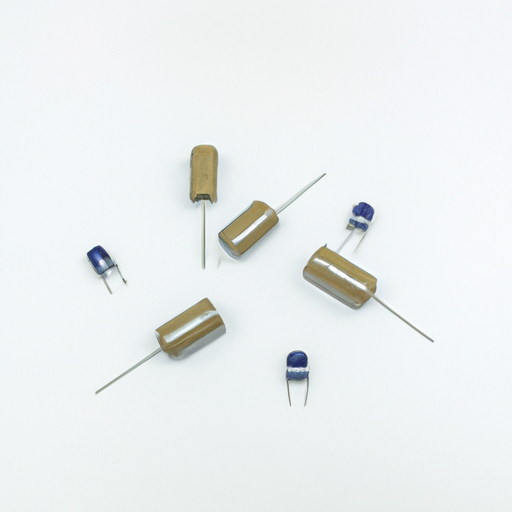

Capacitors are fundamental components in electronic circuits, serving as energy storage devices that can release energy when needed. They play a crucial role in various applications, from power supply smoothing to signal coupling and decoupling. Understanding the different types of capacitors and their popular product models is essential for engineers, hobbyists, and anyone involved in electronics. This article aims to explore the various types of capacitors, highlight popular product models, and provide insights into selecting the right capacitor for specific applications.

II. Types of Capacitors

Capacitors come in various types, each with unique characteristics and applications. Here, we will discuss five common types of capacitors: electrolytic, ceramic, film, tantalum, and supercapacitors.

A. Electrolytic Capacitors

Electrolytic capacitors are polarized components that typically offer high capacitance values in a relatively small package. They are characterized by their ability to store large amounts of energy, making them ideal for applications requiring significant energy storage.

**Common Applications:**

- Power supply filtering

- Audio equipment

- Timing circuits

B. Ceramic Capacitors

Ceramic capacitors are non-polarized capacitors made from ceramic materials. They are known for their stability, low losses, and high-frequency performance. Ceramic capacitors are available in various capacitance values and voltage ratings.

**Common Applications:**

- Decoupling and bypassing in digital circuits

- RF applications

- Timing circuits

C. Film Capacitors

Film capacitors use a thin plastic film as the dielectric material. They are known for their reliability, low self-inductance, and excellent temperature stability. Film capacitors are often used in applications where precision and stability are critical.

**Common Applications:**

- Audio equipment

- Power electronics

- Signal processing

D. Tantalum Capacitors

Tantalum capacitors are known for their high capacitance-to-volume ratio and stable electrical characteristics. They are polarized and are often used in applications where space is limited.

**Common Applications:**

- Mobile devices

- Medical equipment

- Automotive electronics

E. Supercapacitors

Supercapacitors, also known as ultracapacitors, are energy storage devices that bridge the gap between traditional capacitors and batteries. They can store large amounts of energy and deliver it quickly, making them suitable for applications requiring rapid charge and discharge cycles.

**Common Applications:**

- Energy harvesting

- Backup power supplies

- Electric vehicles

III. Popular Capacitor Product Models

Now that we have an overview of the different types of capacitors, let's delve into some popular product models within each category.

A. Electrolytic Capacitors

1. Nichicon UHE Series

Specifications: The Nichicon UHE series features a voltage range of 6.3V to 450V and capacitance values from 1µF to 10000µF. They are designed for long life and high ripple current.

Applications: Commonly used in power supply circuits, audio equipment, and industrial applications.

2. Panasonic FR Series

Specifications: The Panasonic FR series offers a voltage range of 6.3V to 450V and capacitance values from 1µF to 10000µF. They are known for their low ESR and high reliability.

Applications: Ideal for power supply filtering, decoupling, and audio applications.

B. Ceramic Capacitors

1. Murata GRM Series

Specifications: The Murata GRM series includes a wide range of capacitance values (from 1pF to 100µF) and voltage ratings (up to 100V). They are available in various sizes and temperature coefficients.

Applications: Used in decoupling, filtering, and timing applications in consumer electronics.

2. Kemet C4 Series

Specifications: The Kemet C4 series features capacitance values from 1nF to 10µF and voltage ratings up to 100V. They are known for their stability and reliability.

Applications: Commonly used in RF applications, power supplies, and signal processing.

C. Film Capacitors

1. WIMA MKS Series

Specifications: The WIMA MKS series offers capacitance values from 1nF to 10µF and voltage ratings up to 1000V. They are known for their low self-inductance and high stability.

Applications: Ideal for audio applications, power electronics, and signal processing.

2. Vishay BC Components 1832 Series

Specifications: The Vishay 1832 series features capacitance values from 1nF to 10µF and voltage ratings up to 1000V. They are designed for high-frequency applications.

Applications: Commonly used in telecommunications, audio equipment, and industrial applications.

D. Tantalum Capacitors

1. Kemet T491 Series

Specifications: The Kemet T491 series offers capacitance values from 1µF to 1000µF and voltage ratings from 6.3V to 50V. They are known for their high reliability and low ESR.

Applications: Used in mobile devices, automotive electronics, and medical equipment.

2. AVX TPS Series

Specifications: The AVX TPS series features capacitance values from 1µF to 1000µF and voltage ratings from 6.3V to 50V. They are designed for high-performance applications.

Applications: Commonly used in consumer electronics, automotive, and industrial applications.

E. Supercapacitors

1. Maxwell Technologies BMOD Series

Specifications: The Maxwell BMOD series offers capacitance values from 1F to 3000F and voltage ratings up to 3V. They are designed for high energy density and long cycle life.

Applications: Ideal for energy storage in renewable energy systems, backup power supplies, and electric vehicles.

2. Panasonic EEC Series

Specifications: The Panasonic EEC series features capacitance values from 0.1F to 100F and voltage ratings up to 2.7V. They are known for their high power density and long life.

Applications: Commonly used in energy harvesting, backup power, and automotive applications.

IV. Factors to Consider When Choosing Capacitors

When selecting capacitors for a specific application, several factors must be considered:

A. Voltage Rating

The voltage rating indicates the maximum voltage the capacitor can handle without failure. It is essential to choose a capacitor with a voltage rating higher than the maximum voltage in the circuit.

B. Capacitance Value

The capacitance value determines how much charge the capacitor can store. It is crucial to select a capacitance value that meets the requirements of the application.

C. Temperature Coefficient

The temperature coefficient indicates how the capacitance value changes with temperature. Different applications may require capacitors with specific temperature stability.

D. Size and Form Factor

The physical size and form factor of the capacitor can impact its suitability for a particular application, especially in compact electronic devices.

E. Application-Specific Requirements

Certain applications may have unique requirements, such as low ESR, high ripple current capability, or specific frequency response characteristics.

V. Trends in Capacitor Technology

The capacitor industry is continually evolving, with several trends shaping the future of capacitor technology:

A. Miniaturization and High-Capacity Designs

As electronic devices become smaller and more powerful, there is a growing demand for miniaturized capacitors with high capacitance values. Manufacturers are developing new materials and designs to meet these needs.

B. Environmental Considerations and RoHS Compliance

With increasing awareness of environmental issues, many manufacturers are focusing on producing capacitors that comply with RoHS (Restriction of Hazardous Substances) regulations. This trend is driving the development of eco-friendly materials and manufacturing processes.

C. Innovations in Supercapacitor Technology

Supercapacitors are gaining popularity due to their ability to store large amounts of energy and deliver it quickly. Ongoing research is focused on improving their energy density, cycle life, and cost-effectiveness.

VI. Conclusion

Selecting the right capacitor is crucial for the performance and reliability of electronic circuits. Understanding the different types of capacitors and their popular product models can help engineers and hobbyists make informed decisions. From electrolytic to supercapacitors, each type has its unique characteristics and applications. As technology continues to advance, staying updated on trends and innovations in capacitor technology will be essential for anyone involved in electronics.

VII. References

For further reading and research on capacitors and their applications, consider exploring the following sources:

- Manufacturer datasheets and technical documents

- Electronics textbooks and reference guides

- Online electronics forums and communities

- Industry publications and journals on capacitor technology