Popular Models of Common Parallel Capacitors

I. Introduction

Capacitors are fundamental components in electronic circuits, serving as energy storage devices that can influence the performance and functionality of various applications. They store electrical energy in an electric field, allowing them to release it when needed. This property makes capacitors essential for tasks such as filtering, timing, and energy storage in power supply circuits. Among the various configurations of capacitors, parallel capacitors are particularly noteworthy due to their ability to increase total capacitance and enhance circuit stability. This article aims to explore popular models of common parallel capacitors, providing insights into their characteristics, applications, and considerations for selection.

II. Understanding Capacitors

A. Basic Principles of Capacitance

Capacitance is defined as the ability of a capacitor to store charge per unit voltage. It is measured in farads (F), with practical applications often using microfarads (µF) or picofarads (pF). Several factors influence capacitance, including the dielectric material used, the surface area of the capacitor plates, and the distance between them. A larger surface area and a smaller distance between plates result in higher capacitance.

B. Types of Capacitors

Capacitors come in various types, each with unique characteristics and applications:

1. **Electrolytic Capacitors**: Known for their high capacitance values, these capacitors are polarized and typically used in power supply applications.

2. **Ceramic Capacitors**: These capacitors are non-polarized and offer stability and reliability, making them suitable for high-frequency applications.

3. **Film Capacitors**: Made from thin plastic films, these capacitors are known for their low loss and high stability, often used in audio and timing circuits.

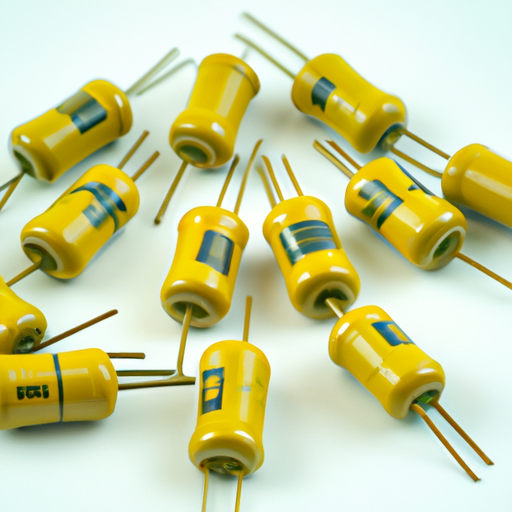

4. **Tantalum Capacitors**: These capacitors provide high capacitance in a small package and are often used in compact electronic devices.

C. Role of Capacitors in Circuits

Capacitors play several critical roles in electronic circuits, including:

1. **Energy Storage**: Capacitors can store energy and release it when needed, making them essential in power supply circuits.

2. **Filtering and Smoothing**: They help filter out noise and smooth voltage fluctuations in power supplies.

3. **Timing Applications**: Capacitors are used in timing circuits, where they charge and discharge at specific rates to create time delays.

III. Parallel Capacitors: An Overview

A. Definition and Explanation of Parallel Capacitors

When capacitors are connected in parallel, their capacitance values add together. This configuration allows for a greater total capacitance than any individual capacitor, which can be beneficial in various applications. For example, if two capacitors with capacitance values of 10 µF and 20 µF are connected in parallel, the total capacitance will be 30 µF.

B. Advantages of Using Parallel Capacitors

1. **Increased Capacitance**: The primary advantage of connecting capacitors in parallel is the increase in total capacitance, which can enhance the performance of the circuit.

2. **Improved Stability and Performance**: Parallel capacitors can provide better voltage stability and reduce the effects of equivalent series resistance (ESR), leading to improved overall performance.

C. Applications of Parallel Capacitors in Circuits

Parallel capacitors are commonly used in power supply circuits, audio equipment, and signal processing applications. They help ensure stable voltage levels and improve the overall efficiency of electronic devices.

IV. Popular Models of Common Parallel Capacitors

A. Overview of Popular Capacitor Models

Several popular models of capacitors are widely used in electronic applications. Each type has its unique characteristics, making them suitable for specific uses.

B. Detailed Examination of Specific Models

1. Ceramic Capacitors

Characteristics and Specifications: Ceramic capacitors are known for their small size, low cost, and high stability. They typically have capacitance values ranging from a few picofarads to several microfarads.

Common Applications: These capacitors are often used in high-frequency applications, decoupling, and filtering.

Popular Brands and Models: Notable manufacturers include Murata and Kemet, which offer a range of ceramic capacitors suitable for various applications.

2. Electrolytic Capacitors

Characteristics and Specifications: Electrolytic capacitors are polarized and have high capacitance values, often exceeding 100 µF. They are typically used in applications requiring significant energy storage.

Common Applications: These capacitors are commonly found in power supply circuits, audio equipment, and smoothing applications.

Popular Brands and Models: Brands like Nichicon and Panasonic are well-known for their reliable electrolytic capacitors.

3. Film Capacitors

Characteristics and Specifications: Film capacitors are known for their low loss, high stability, and excellent performance in audio applications. They typically have capacitance values ranging from a few nanofarads to several microfarads.

Common Applications: These capacitors are often used in audio circuits, timing applications, and filtering.

Popular Brands and Models: WIMA and Vishay are prominent manufacturers of film capacitors, offering a variety of models for different applications.

4. Tantalum Capacitors

Characteristics and Specifications: Tantalum capacitors provide high capacitance in a compact size, making them ideal for space-constrained applications. They are also polarized and have a voltage rating that can vary significantly.

Common Applications: These capacitors are commonly used in portable electronics, power supply circuits, and decoupling applications.

Popular Brands and Models: Kemet and AVX are leading manufacturers of tantalum capacitors, known for their reliability and performance.

V. Factors to Consider When Choosing Parallel Capacitors

When selecting parallel capacitors for a specific application, several factors should be considered:

A. Capacitance Value and Tolerance

The required capacitance value and its tolerance are critical for ensuring the capacitor meets the circuit's needs.

B. Voltage Rating

The voltage rating of the capacitor must exceed the maximum voltage it will encounter in the circuit to prevent failure.

C. Temperature Coefficient

Different capacitors have varying temperature coefficients, which can affect their performance in different temperature environments.

D. Size and Form Factor

The physical size and form factor of the capacitor can impact its suitability for specific applications, especially in compact electronic devices.

E. Application-Specific Requirements

Consideration of the specific requirements of the application, such as frequency response and ESR, is essential for selecting the right capacitor.

VI. Practical Applications of Parallel Capacitors

Parallel capacitors find applications in various electronic circuits, including:

A. Power Supply Circuits

In power supply circuits, parallel capacitors help smooth voltage fluctuations and provide stable power to components.

B. Audio Equipment

In audio applications, parallel capacitors are used to filter out noise and improve sound quality.

C. Signal Processing

Parallel capacitors play a crucial role in signal processing, where they help maintain signal integrity and reduce distortion.

D. Timing Circuits

In timing circuits, capacitors are used to create time delays and control the timing of signals.

E. Filtering Applications

Parallel capacitors are commonly used in filtering applications to remove unwanted frequencies and improve overall circuit performance.

VII. Conclusion

In conclusion, parallel capacitors are essential components in electronic circuits, providing increased capacitance and improved stability. Understanding the characteristics and applications of popular capacitor models, such as ceramic, electrolytic, film, and tantalum capacitors, is crucial for selecting the right component for specific needs. By considering factors such as capacitance value, voltage rating, and application requirements, engineers and hobbyists can make informed decisions that enhance the performance of their electronic designs.

VIII. References

For further reading on capacitors and electronics, consider the following resources:

- "The Art of Electronics" by Paul Horowitz and Winfield Hill

- "Capacitors: Technology and Applications" by John W. McCulloch

- Online resources such as Digi-Key and Mouser Electronics for datasheets and product specifications.