What is the Working Principle of Capacitor Manufacturers?

I. Introduction

Capacitors are fundamental components in electronic circuits, serving as energy storage devices that can release energy when needed. They play a crucial role in various applications, from smoothing out voltage fluctuations in power supplies to enabling signal processing in communication devices. The capacitor manufacturing industry is a vital sector that supports the growing demand for electronic devices, driven by advancements in technology and the increasing reliance on electronic systems in everyday life.

II. Understanding Capacitors

A. Basic Principles of Capacitance

At its core, capacitance is the ability of a component to store electrical energy in an electric field. The capacitance (C) of a capacitor is defined as the ratio of the electric charge (Q) stored on one plate to the voltage (V) across the plates:

\[ C = \frac{Q}{V} \]

Several factors influence capacitance:

1. **Dielectric Material**: The insulating material between the capacitor plates affects how much charge can be stored. Different materials have different dielectric constants, which determine their effectiveness in storing energy.

2. **Surface Area**: The larger the surface area of the plates, the more charge can be stored, leading to higher capacitance.

3. **Distance Between Plates**: The closer the plates are to each other, the stronger the electric field and the greater the capacitance. However, reducing the distance too much can lead to dielectric breakdown.

B. Types of Capacitors

Capacitors come in various types, each suited for specific applications:

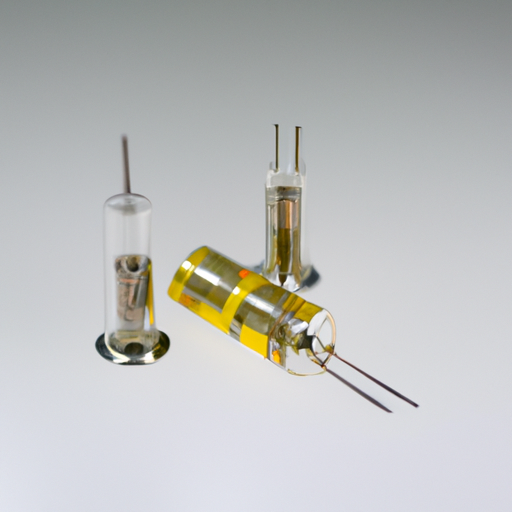

1. **Electrolytic Capacitors**: These capacitors use an electrolyte as one of the plates, allowing for high capacitance values in a compact size. They are polarized, meaning they must be connected in the correct direction in a circuit.

2. **Ceramic Capacitors**: Made from ceramic materials, these capacitors are non-polarized and are commonly used in high-frequency applications due to their stability and low losses.

3. **Film Capacitors**: These capacitors use thin plastic films as dielectrics. They are known for their reliability and are often used in audio and power applications.

4. **Tantalum Capacitors**: Similar to electrolytic capacitors but made with tantalum metal, these capacitors offer high capacitance in a small package and are used in applications where space is limited.

5. **Supercapacitors**: Also known as ultracapacitors, these devices can store large amounts of energy and are used in applications requiring rapid charge and discharge cycles, such as energy storage systems.

III. The Capacitor Manufacturing Process

A. Raw Materials Used in Capacitor Production

The manufacturing of capacitors begins with the selection of raw materials:

1. **Dielectric Materials**: The choice of dielectric material is critical, as it directly affects the capacitor's performance. Common materials include ceramic, polyester, and tantalum oxide.

2. **Conductive Materials**: Metals such as aluminum and tantalum are used for the plates, while conductive pastes may be used in some types of capacitors.

B. Steps in the Manufacturing Process

The manufacturing process of capacitors involves several key steps:

1. **Material Preparation**: Raw materials are processed to meet specific requirements. For example, aluminum foils are etched to increase surface area, while dielectric films are produced in controlled environments to ensure uniform thickness.

2. **Layering and Assembly**: The prepared materials are layered according to the type of capacitor being produced. For instance, in electrolytic capacitors, the dielectric is placed between two conductive plates, and the assembly is rolled or stacked.

3. **Impregnation**: In the case of electrolytic capacitors, the assembly is impregnated with an electrolyte solution, which enhances the capacitor's performance and longevity.

4. **Encapsulation and Packaging**: The final step involves encapsulating the capacitor in protective materials to prevent damage and ensure reliability. This may include sealing the capacitor in a plastic or metal casing.

C. Quality Control Measures

Quality control is paramount in capacitor manufacturing. Manufacturers conduct rigorous testing to ensure that each capacitor meets specified standards:

1. **Testing for Capacitance and Leakage**: Capacitors are tested for their capacitance values and leakage currents to ensure they function correctly within their specified limits.

2. **Reliability Testing**: Manufacturers perform stress tests, including temperature cycling and voltage stress tests, to assess the long-term reliability of the capacitors.

IV. Technological Innovations in Capacitor Manufacturing

A. Advances in Materials Science

The capacitor manufacturing industry has seen significant advancements in materials science:

1. **Development of New Dielectric Materials**: Researchers are continually exploring new dielectric materials that offer higher capacitance and better performance, such as organic polymers and advanced ceramics.

2. **Nanotechnology in Capacitors**: The application of nanotechnology has led to the development of capacitors with improved energy density and faster charge/discharge rates.

B. Automation and Robotics in Manufacturing

Automation and robotics have revolutionized the manufacturing process, increasing efficiency and precision. Automated systems can handle repetitive tasks, reducing human error and improving production rates.

C. Environmental Considerations and Sustainable Practices

As environmental concerns grow, capacitor manufacturers are adopting sustainable practices. This includes using eco-friendly materials, reducing waste, and implementing energy-efficient manufacturing processes.

V. Challenges Faced by Capacitor Manufacturers

Despite the advancements, capacitor manufacturers face several challenges:

A. Supply Chain Issues

Global supply chain disruptions can impact the availability of raw materials, leading to production delays and increased costs.

B. Competition and Market Dynamics

The capacitor market is highly competitive, with numerous manufacturers vying for market share. Companies must continuously innovate to stay ahead.

C. Regulatory Compliance and Environmental Regulations

Manufacturers must navigate complex regulatory environments and comply with environmental regulations, which can vary by region and impact production processes.

VI. Future Trends in Capacitor Manufacturing

The future of capacitor manufacturing is shaped by several trends:

A. Growth of Electric Vehicles and Renewable Energy

The rise of electric vehicles and renewable energy sources is driving demand for advanced capacitors, particularly in energy storage applications.

B. Miniaturization and High-Capacity Demands

As electronic devices become smaller and more powerful, there is a growing need for miniaturized capacitors that can deliver high capacitance in compact sizes.

C. Research and Development in Energy Storage Solutions

Ongoing research in energy storage technologies, including supercapacitors and hybrid systems, is expected to lead to innovative capacitor designs that meet the evolving needs of various industries.

VII. Conclusion

Capacitors are essential components in modern electronics, and their manufacturing involves a complex interplay of materials science, engineering, and quality control. As technology continues to advance, capacitor manufacturers play a crucial role in supporting innovation across various sectors. The future of the capacitor manufacturing industry looks promising, with opportunities for growth driven by emerging technologies and increasing demand for energy-efficient solutions.

VIII. References

1. Academic journals and articles on capacitor technology and materials science.

2. Industry reports detailing market trends and forecasts for the capacitor manufacturing sector.

3. Books on electronics, capacitor design, and manufacturing processes.

In summary, understanding the working principles of capacitor manufacturers provides valuable insights into the intricate processes that enable the production of these vital components, highlighting their significance in the ever-evolving landscape of technology.