What Industries Are the Application Scenarios of Ceramic Capacitors Included In?

I. Introduction

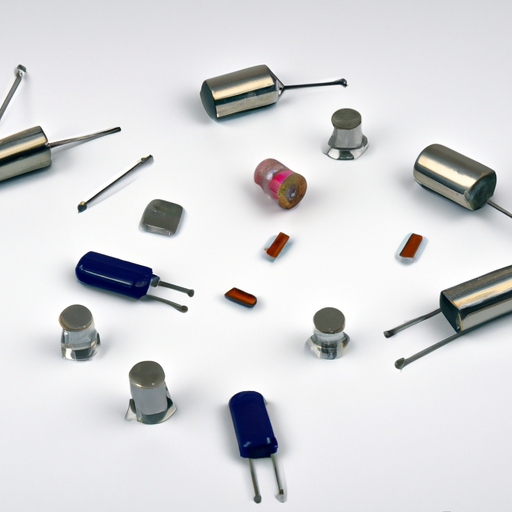

Ceramic capacitors are essential components in modern electronics, known for their reliability, stability, and versatility. These passive electronic devices store and release electrical energy, playing a crucial role in filtering, decoupling, and timing applications. As technology continues to advance, the demand for ceramic capacitors has surged, leading to their widespread use across various industries. This blog post explores the diverse application scenarios of ceramic capacitors, highlighting their significance in the electronics, industrial, medical, aerospace, and renewable energy sectors.

II. Electronics Industry

A. Consumer Electronics

The consumer electronics sector is one of the largest markets for ceramic capacitors. These components are integral to the functionality of devices that have become ubiquitous in our daily lives.

1. **Smartphones and Tablets**: Ceramic capacitors are used in smartphones and tablets for power management, signal processing, and noise filtering. Their small size and high capacitance values make them ideal for compact devices that require efficient energy storage and management.

2. **Laptops and Desktops**: In laptops and desktops, ceramic capacitors are employed in power supply circuits, motherboards, and graphics cards. They help stabilize voltage levels and reduce electromagnetic interference, ensuring smooth operation and enhanced performance.

3. **Wearable Devices**: The rise of wearable technology, such as smartwatches and fitness trackers, has further increased the demand for ceramic capacitors. Their lightweight and compact nature allows for integration into small form factors while providing reliable performance.

B. Telecommunications

The telecommunications industry relies heavily on ceramic capacitors for various applications, ensuring efficient communication and data transfer.

1. **Base Stations**: Ceramic capacitors are used in base stations to filter signals and stabilize power supplies. They help maintain signal integrity and reduce noise, which is critical for reliable communication.

2. **Networking Equipment**: In routers, switches, and other networking devices, ceramic capacitors play a vital role in managing power and ensuring stable operation. They help mitigate voltage fluctuations and enhance the performance of high-speed data transmission.

3. **Signal Processing Devices**: Ceramic capacitors are essential in signal processing applications, where they are used in filters and oscillators. Their ability to operate at high frequencies makes them suitable for advanced telecommunications systems.

C. Automotive Electronics

The automotive industry has seen a significant transformation with the integration of advanced electronics, and ceramic capacitors are at the forefront of this evolution.

1. **Infotainment Systems**: Modern vehicles are equipped with sophisticated infotainment systems that require reliable power management. Ceramic capacitors are used to filter noise and stabilize power supplies, ensuring optimal performance of audio and navigation systems.

2. **Advanced Driver-Assistance Systems (ADAS)**: ADAS technologies, such as lane departure warning and adaptive cruise control, rely on precise electronic components. Ceramic capacitors are crucial for signal processing and power management in these systems, enhancing safety and performance.

3. **Electric Vehicles (EVs)**: As the automotive industry shifts towards electric vehicles, the demand for ceramic capacitors has increased. They are used in battery management systems, power inverters, and charging stations, contributing to the efficiency and reliability of EVs.

III. Industrial Applications

Ceramic capacitors are also widely used in various industrial applications, where they contribute to automation, power management, and measurement.

A. Automation and Control Systems

1. **Programmable Logic Controllers (PLCs)**: In industrial automation, PLCs are essential for controlling machinery and processes. Ceramic capacitors are used in these systems to filter noise and stabilize power supplies, ensuring reliable operation.

2. **Robotics**: The robotics industry relies on ceramic capacitors for power management and signal processing. They help maintain the performance of sensors and actuators, which are critical for the precise operation of robotic systems.

B. Power Supply Systems

1. **Uninterruptible Power Supplies (UPS)**: Ceramic capacitors are used in UPS systems to provide backup power during outages. They help stabilize voltage levels and ensure a smooth transition between power sources.

2. **Power Converters**: In power conversion applications, ceramic capacitors are employed to filter and smooth out voltage fluctuations. Their high-frequency performance makes them ideal for use in inverters and converters.

C. Measurement and Testing Equipment

1. **Oscilloscopes**: Ceramic capacitors are integral to oscilloscopes, where they help filter signals and stabilize power supplies. This ensures accurate measurements and reliable performance in testing applications.

2. **Signal Analyzers**: In signal analysis, ceramic capacitors are used to manage power and filter noise, enabling precise analysis of electronic signals.

IV. Medical Devices

The medical industry relies on ceramic capacitors for various applications, where reliability and precision are paramount.

A. Diagnostic Equipment

1. **MRI Machines**: Ceramic capacitors are used in MRI machines to manage power and filter signals. Their stability and reliability are critical for producing high-quality images.

2. **Ultrasound Devices**: In ultrasound equipment, ceramic capacitors help stabilize power supplies and filter noise, ensuring accurate imaging and diagnostics.

B. Therapeutic Equipment

1. **Pacemakers**: Ceramic capacitors are essential in pacemakers, where they help manage power and ensure reliable operation. Their small size and high reliability make them ideal for use in life-sustaining devices.

2. **Infusion Pumps**: In infusion pumps, ceramic capacitors are used to stabilize power supplies and ensure precise delivery of medication, enhancing patient safety and care.

C. Wearable Health Monitors

1. **Fitness Trackers**: Ceramic capacitors are used in fitness trackers to manage power and filter signals. Their compact size allows for integration into small devices, providing reliable performance.

2. **Continuous Glucose Monitors**: In continuous glucose monitoring systems, ceramic capacitors help stabilize power supplies and ensure accurate readings, contributing to effective diabetes management.

V. Aerospace and Defense

The aerospace and defense sectors require high-performance components, and ceramic capacitors are widely used in various applications.

A. Avionics Systems

1. **Navigation and Communication Systems**: Ceramic capacitors are critical in avionics systems, where they help filter signals and stabilize power supplies. This ensures reliable communication and navigation in aircraft.

2. **Flight Control Systems**: In flight control systems, ceramic capacitors are used to manage power and filter noise, contributing to the safety and performance of aircraft.

B. Military Applications

1. **Radar Systems**: Ceramic capacitors are essential in radar systems, where they help stabilize power and filter signals. Their reliability is crucial for effective surveillance and targeting.

2. **Electronic Warfare Systems**: In electronic warfare applications, ceramic capacitors are used to manage power and filter signals, ensuring effective operation in challenging environments.

VI. Renewable Energy

As the world shifts towards sustainable energy solutions, ceramic capacitors play a vital role in renewable energy applications.

A. Solar Power Systems

1. **Inverters**: Ceramic capacitors are used in solar inverters to filter and stabilize power. Their high-frequency performance is essential for efficient energy conversion.

2. **Energy Storage Systems**: In energy storage systems, ceramic capacitors help manage power and ensure reliable operation, contributing to the efficiency of solar power systems.

B. Wind Energy

1. **Control Systems**: In wind turbines, ceramic capacitors are used in control systems to manage power and filter signals, ensuring optimal performance and reliability.

2. **Power Management**: Ceramic capacitors play a crucial role in power management systems for wind energy, helping to stabilize voltage and enhance efficiency.

VII. Conclusion

Ceramic capacitors are integral to a wide range of industries, from consumer electronics to aerospace and renewable energy. Their reliability, stability, and versatility make them essential components in modern technology. As industries continue to evolve and innovate, the demand for ceramic capacitors is expected to grow, driving advancements in capacitor technology. The ongoing importance of ceramic capacitors across various sectors underscores their role in shaping the future of electronics and technology. With continuous research and development, we can anticipate even more innovative applications and improvements in ceramic capacitor performance, further solidifying their place in the ever-evolving landscape of modern electronics.