What are the Latest Manufacturing Processes for Resistor Packaging?

I. Introduction

Resistor packaging is a critical aspect of electronic device design and manufacturing. It involves enclosing resistors in protective casings that ensure their functionality and reliability in various applications. As electronic devices become increasingly compact and complex, the importance of effective resistor packaging has grown significantly. This blog post will explore the latest manufacturing processes for resistor packaging, highlighting the evolution of these processes and their impact on the electronics industry.

II. Types of Resistor Packaging

A. Through-Hole Resistors

Through-hole resistors are one of the oldest types of resistor packaging. They consist of a cylindrical body with leads that pass through the printed circuit board (PCB). These resistors are commonly used in applications where durability and stability are paramount, such as in power supplies and audio equipment. Traditional manufacturing processes for through-hole resistors involve winding a resistive wire around a ceramic core and then encapsulating it in a protective coating.

B. Surface-Mount Resistors

Surface-mount resistors (SMDs) have gained popularity due to their compact size and ease of integration into modern PCBs. These resistors are mounted directly onto the surface of the PCB, allowing for higher component density and reduced manufacturing costs. Modern manufacturing processes for SMDs include automated pick-and-place technology, which streamlines the assembly process and enhances precision.

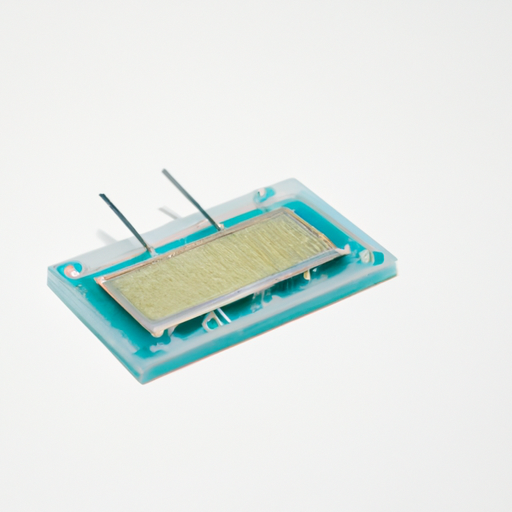

C. Chip Resistors

Chip resistors are a type of surface-mount resistor that is even smaller and more efficient. They are typically made from thin films of resistive material deposited onto a substrate. Innovations in manufacturing chip resistors include advanced deposition techniques and the use of high-performance materials, which enhance their reliability and performance in high-frequency applications.

III. Key Manufacturing Processes

A. Material Selection

The selection of materials is crucial in resistor packaging. Conductive materials, such as metal films or carbon compositions, are chosen based on their resistive properties and thermal stability. Substrate materials, like ceramic or polymer, must provide adequate insulation and mechanical support. Additionally, environmental considerations, such as the use of lead-free materials, are increasingly important in the manufacturing process.

B. Printing Technologies

Printing technologies have revolutionized resistor manufacturing.

1. **Screen Printing**: This traditional method involves applying a paste of conductive material onto a substrate through a mesh screen. It is widely used for producing thick-film resistors.

2. **Inkjet Printing**: This modern technique allows for precise deposition of conductive inks, enabling the creation of complex resistor patterns on various substrates. Inkjet printing is particularly advantageous for prototyping and low-volume production.

3. **3D Printing**: Emerging as a game-changer, 3D printing technology enables the fabrication of resistors with intricate geometries and customized properties. This method allows for rapid prototyping and the production of unique designs that were previously impossible.

C. Sintering Techniques

Sintering is a critical process in resistor manufacturing that involves heating materials to form a solid mass without melting them.

1. **Conventional Sintering**: This traditional method requires long heating times and high temperatures, which can affect the properties of the resistor.

2. **Advanced Sintering Methods**: Techniques such as microwave sintering have emerged, offering faster processing times and improved material properties. Microwave sintering uses electromagnetic waves to heat materials uniformly, resulting in better densification and performance.

D. Encapsulation and Coating

Encapsulation and coating are essential for protecting resistors from environmental factors.

1. **Epoxy and Silicone Coatings**: These materials provide excellent protection against moisture, dust, and mechanical stress, ensuring the longevity of resistors in various applications.

2. **Environmental Protection Methods**: Advanced coatings, such as conformal coatings, are applied to PCBs to protect against environmental hazards, enhancing the reliability of the entire electronic assembly.

E. Automated Assembly Processes

Automation has transformed the assembly of resistors, leading to increased efficiency and precision.

1. **Pick-and-Place Technology**: This automated process involves using robotic arms to place resistors onto PCBs with high accuracy, significantly reducing assembly time and labor costs.

2. **Robotic Assembly Lines**: Fully automated assembly lines can handle multiple components simultaneously, streamlining the manufacturing process and minimizing human error.

IV. Innovations in Resistor Packaging

A. Miniaturization Trends

The trend toward miniaturization has had a profound impact on resistor packaging. As electronic devices shrink, manufacturers are challenged to produce smaller, more efficient resistors without compromising performance. Solutions include the development of ultra-thin chip resistors and advanced packaging techniques that maximize space utilization.

B. Smart Resistors

The integration of sensors and IoT capabilities into resistors is an exciting innovation. Smart resistors can monitor their own performance and communicate data to other devices, enhancing the functionality of electronic systems. The manufacturing implications include the need for new materials and processes to accommodate these advanced features.

C. Sustainable Practices

Sustainability is becoming a priority in resistor manufacturing.

1. **Eco-Friendly Materials**: Manufacturers are increasingly using biodegradable and recyclable materials in resistor packaging to reduce environmental impact.

2. **Waste Reduction Techniques**: Lean manufacturing practices and recycling initiatives are being implemented to minimize waste during the production process.

V. Quality Control and Testing

Quality assurance is paramount in resistor packaging to ensure reliability and performance.

A. Importance of Quality Assurance

Quality control processes help identify defects and ensure that resistors meet industry standards. This is crucial for maintaining the integrity of electronic devices.

B. Testing Methods

1. **Electrical Testing**: Resistors undergo rigorous electrical testing to verify their resistance values and performance under various conditions.

2. **Environmental Testing**: Resistors are subjected to environmental tests, such as temperature cycling and humidity exposure, to assess their durability.

3. **Reliability Testing**: Long-term reliability tests simulate real-world conditions to ensure that resistors will perform consistently over time.

C. Role of Automation in Quality Control

Automation plays a significant role in quality control, with advanced inspection systems using machine learning algorithms to detect defects and ensure compliance with specifications.

VI. Future Trends in Resistor Packaging

A. Emerging Technologies

The future of resistor packaging is likely to be shaped by emerging technologies such as nanotechnology and flexible electronics.

1. **Nanotechnology**: The use of nanomaterials can enhance the performance and miniaturization of resistors, leading to more efficient electronic devices.

2. **Flexible Electronics**: As the demand for flexible and wearable devices grows, resistor packaging will need to adapt to new form factors and materials.

B. Market Demands

Market demands for smaller, more efficient, and environmentally friendly components will continue to influence manufacturing processes. Manufacturers must stay agile and innovative to meet these evolving requirements.

C. Predictions for the Next Decade

In the next decade, we can expect significant advancements in resistor packaging, driven by technological innovations and sustainability initiatives. The integration of AI and machine learning in manufacturing processes will further enhance efficiency and quality.

VII. Conclusion

In summary, the latest manufacturing processes for resistor packaging reflect the ongoing evolution of the electronics industry. From material selection and printing technologies to automation and sustainability practices, these processes are crucial for producing reliable and efficient resistors. As technology continues to advance, the significance of ongoing innovation in resistor packaging will only grow, shaping the future of electronic devices.

VIII. References

1. Academic journals on electronics and materials science.

2. Industry reports from leading electronics manufacturers.

3. Relevant books and articles on resistor packaging and manufacturing processes.

This comprehensive overview of the latest manufacturing processes for resistor packaging highlights the importance of innovation and adaptation in a rapidly changing industry. As we look to the future, the continued evolution of these processes will play a vital role in the development of next-generation electronic devices.