What are the Advantages of Standard Capacitor Products?

I. Introduction

Capacitors are fundamental components in electronic circuits, serving various roles such as energy storage, filtering, and signal coupling. A standard capacitor is a pre-manufactured component that adheres to established specifications and dimensions, making it widely available and easily interchangeable. This article aims to explore the advantages of standard capacitor products, highlighting their significance in modern electronics and the benefits they offer to engineers and designers.

II. Overview of Capacitor Types

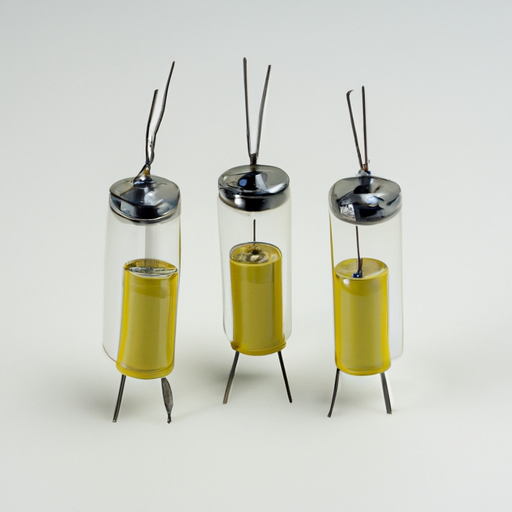

Capacitors come in various types, each with unique characteristics and applications. Understanding these types is essential for recognizing the advantages of standard capacitor products.

A. Types of Capacitors

1. **Electrolytic Capacitors**: Known for their high capacitance values, electrolytic capacitors are polarized components often used in power supply circuits. They are ideal for applications requiring significant energy storage.

2. **Ceramic Capacitors**: These capacitors are non-polarized and are widely used in high-frequency applications due to their low equivalent series resistance (ESR). They are available in various capacitance values and voltage ratings.

3. **Film Capacitors**: Made from thin plastic films, these capacitors are known for their stability and reliability. They are commonly used in audio applications and power electronics.

4. **Tantalum Capacitors**: Tantalum capacitors offer high capacitance in a small package and are often used in compact electronic devices. They are known for their reliability but can be more expensive than other types.

B. Explanation of Standard Capacitors vs. Custom Capacitors

Standard capacitors are mass-produced components that conform to industry standards, while custom capacitors are tailored to specific requirements. While custom capacitors can meet unique needs, they often come with higher costs, longer lead times, and potential reliability issues. In contrast, standard capacitors provide a reliable and cost-effective solution for many applications.

III. Advantages of Standard Capacitor Products

Standard capacitor products offer numerous advantages that make them a preferred choice for engineers and designers.

A. Cost-Effectiveness

1. **Economies of Scale in Production**: Standard capacitors are produced in large quantities, allowing manufacturers to benefit from economies of scale. This results in lower production costs, which are passed on to consumers.

2. **Lower Prices Compared to Custom Solutions**: Because standard capacitors are mass-produced, they are generally more affordable than custom capacitors, making them an attractive option for budget-conscious projects.

B. Availability and Accessibility

1. **Wide Range of Options in the Market**: The market for standard capacitors is vast, with numerous options available in various capacitance values, voltage ratings, and sizes. This variety allows engineers to find the right component for their specific needs.

2. **Easy Procurement from Various Suppliers**: Standard capacitors are widely available from multiple suppliers, making it easy for engineers to source components quickly and efficiently.

C. Reliability and Quality Assurance

1. **Established Manufacturing Standards**: Standard capacitors are produced according to established industry standards, ensuring consistent quality and performance. This reliability is crucial in applications where failure is not an option.

2. **Consistent Performance Metrics**: Standard capacitors undergo rigorous testing and quality control, providing engineers with confidence in their performance metrics, such as capacitance tolerance and ESR.

D. Compatibility and Interchangeability

1. **Standardized Sizes and Ratings**: Standard capacitors come in standardized sizes and ratings, making it easier for engineers to design circuits without worrying about compatibility issues.

2. **Simplified Design Processes for Engineers**: The availability of standardized components simplifies the design process, allowing engineers to focus on innovation rather than component selection.

E. Time Efficiency

1. **Reduced Lead Times for Procurement**: Standard capacitors are readily available, resulting in shorter lead times for procurement. This is particularly beneficial in fast-paced industries where time-to-market is critical.

2. **Faster Design Cycles Due to Readily Available Components**: With standard capacitors, engineers can quickly prototype and iterate on designs, leading to faster development cycles and quicker product launches.

F. Technical Support and Documentation

1. **Availability of Datasheets and Application Notes**: Manufacturers of standard capacitors provide comprehensive datasheets and application notes, offering engineers valuable information on component specifications and usage.

2. **Access to Customer Support from Manufacturers**: Many manufacturers offer customer support services, allowing engineers to seek assistance with technical questions or issues related to standard capacitors.

IV. Applications of Standard Capacitor Products

Standard capacitors find applications across various industries, demonstrating their versatility and importance.

A. Consumer Electronics

In consumer electronics, standard capacitors are used in devices such as smartphones, tablets, and televisions. They play a crucial role in power management, signal processing, and noise filtering.

B. Automotive Industry

The automotive industry relies on standard capacitors for various applications, including power supply circuits, audio systems, and electronic control units. Their reliability is essential for ensuring vehicle safety and performance.

C. Industrial Equipment

Standard capacitors are widely used in industrial equipment for energy storage, filtering, and timing applications. Their robustness and reliability make them suitable for demanding environments.

D. Telecommunications

In telecommunications, standard capacitors are used in signal processing and power supply circuits. Their performance and reliability are critical for maintaining communication quality.

E. Renewable Energy Systems

Standard capacitors play a vital role in renewable energy systems, such as solar inverters and wind turbines. They help manage energy storage and conversion, contributing to the efficiency of these systems.

V. Challenges and Considerations

While standard capacitors offer numerous advantages, there are also challenges and considerations to keep in mind.

A. Limitations of Standard Capacitors

1. **Performance Constraints in Specialized Applications**: Standard capacitors may not meet the specific performance requirements of specialized applications, necessitating the use of custom solutions.

2. **Potential for Obsolescence**: As technology evolves, certain standard capacitor products may become obsolete, requiring engineers to adapt to new components.

B. Importance of Selecting the Right Capacitor

1. **Understanding Application Requirements**: Engineers must thoroughly understand their application requirements to select the appropriate standard capacitor, considering factors such as capacitance, voltage rating, and temperature stability.

2. **Evaluating Specifications and Ratings**: It is essential to evaluate the specifications and ratings of standard capacitors to ensure they meet the demands of the application.

VI. Conclusion

In summary, standard capacitor products offer a range of advantages, including cost-effectiveness, availability, reliability, compatibility, time efficiency, and technical support. These benefits make them a preferred choice for engineers and designers across various industries. As technology continues to advance, standard capacitors will play a crucial role in the development of modern electronic devices. Engineers and designers are encouraged to consider standard options in their projects, leveraging the advantages they provide to enhance performance and efficiency.

VII. References

A. List of sources for further reading

B. Suggested manufacturers and suppliers of standard capacitors

---

This blog post provides a comprehensive overview of the advantages of standard capacitor products, emphasizing their significance in modern electronics and encouraging engineers to utilize them in their designs.