What are the Latest Capacitor Protection Equipment Components Procurement Models?

I. Introduction

Capacitor protection equipment plays a crucial role in ensuring the reliability and efficiency of electrical systems. These components safeguard capacitors from various electrical disturbances, thereby preventing failures that could lead to costly downtime or damage to equipment. As the demand for reliable electrical systems grows, so does the need for effective procurement models that can streamline the acquisition of capacitor protection equipment. This blog post will explore the latest procurement models in this field, highlighting their significance and the factors influencing their adoption.

II. Understanding Capacitor Protection Equipment

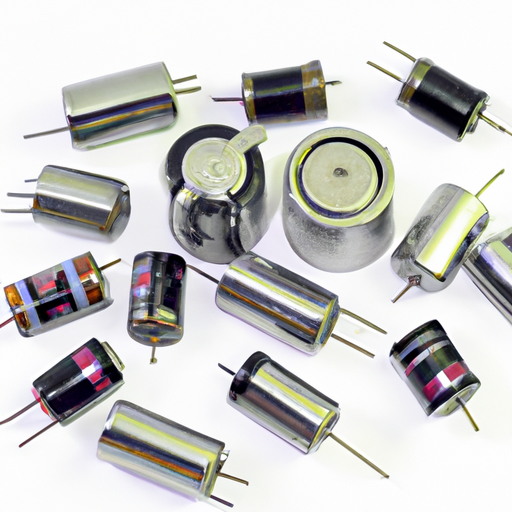

A. Types of Capacitor Protection Equipment

1. **Surge Protection Devices (SPDs)**: These devices protect electrical systems from voltage spikes caused by lightning strikes or switching operations. They divert excess voltage away from sensitive equipment, ensuring operational continuity.

2. **Fuses and Circuit Breakers**: These components are essential for protecting circuits from overloads and short circuits. Fuses melt to break the circuit, while circuit breakers can be reset after tripping, making them a more sustainable option.

3. **Capacitor Banks and Reactors**: Capacitor banks improve power factor and voltage stability, while reactors help in controlling harmonic distortion. Both are vital for maintaining the health of electrical systems.

B. Role of Capacitor Protection in Enhancing System Reliability

Capacitor protection equipment enhances system reliability by preventing failures that can lead to significant operational disruptions. By mitigating risks associated with electrical disturbances, these components ensure that systems operate efficiently and safely.

C. Common Applications of Capacitor Protection Equipment

Capacitor protection equipment is widely used in various sectors, including utilities, manufacturing, and commercial buildings. These applications range from power factor correction in industrial settings to voltage regulation in residential areas.

III. Procurement Models in Capacitor Protection Equipment

A. Traditional Procurement Models

1. **Direct Purchasing**: This straightforward approach involves buying equipment directly from manufacturers or suppliers. While it can be efficient, it may not always yield the best prices or terms.

2. **Request for Proposals (RFPs)**: RFPs allow organizations to solicit bids from multiple suppliers, fostering competition and potentially leading to better pricing and service terms.

3. **Competitive Bidding**: Similar to RFPs, competitive bidding involves inviting suppliers to submit their best offers. This model is often used for larger projects where cost savings are critical.

B. Modern Procurement Models

1. **E-Procurement Platforms**: These digital platforms streamline the procurement process, allowing organizations to manage purchases online. They enhance transparency, reduce paperwork, and can lead to cost savings.

2. **Collaborative Procurement**: This model involves multiple organizations working together to procure equipment. By pooling resources, they can negotiate better terms and prices.

3. **Just-in-Time (JIT) Procurement**: JIT procurement focuses on acquiring equipment only as needed, reducing inventory costs and minimizing waste. This model requires strong supplier relationships and reliable logistics.

C. Hybrid Models

1. **Combining Traditional and Modern Approaches**: Hybrid models leverage the strengths of both traditional and modern procurement methods. For instance, an organization might use RFPs for large purchases while utilizing e-procurement for smaller, routine orders.

2. **Benefits of Hybrid Models in Capacitor Protection Procurement**: Hybrid models can enhance flexibility, allowing organizations to adapt their procurement strategies based on specific needs and market conditions.

IV. Factors Influencing Procurement Models

A. Market Trends and Technological Advancements

The rapid evolution of technology influences procurement models significantly. Organizations must stay abreast of market trends to ensure they are using the most effective procurement strategies.

B. Regulatory and Compliance Considerations

Compliance with industry regulations can dictate procurement practices. Organizations must ensure that their procurement models align with legal requirements and industry standards.

C. Cost Considerations and Budget Constraints

Budget constraints often drive procurement decisions. Organizations must balance the need for quality equipment with the necessity of staying within budget.

D. Supplier Relationships and Management

Strong relationships with suppliers can enhance procurement efficiency. Organizations that invest in supplier management often benefit from better pricing, service, and reliability.

V. Case Studies of Successful Procurement Models

A. Case Study 1: Implementation of E-Procurement in a Utility Company

1. **Overview of the Company and Its Needs**: A regional utility company faced challenges in managing its procurement processes, leading to delays and increased costs.

2. **Steps Taken to Implement E-Procurement**: The company adopted an e-procurement platform that allowed for streamlined purchasing, improved tracking, and enhanced supplier communication.

3. **Outcomes and Lessons Learned**: The implementation resulted in a 20% reduction in procurement costs and improved supplier relationships. The company learned the importance of training staff to maximize the platform's potential.

B. Case Study 2: Collaborative Procurement in a Manufacturing Setting

1. **Description of the Manufacturing Environment**: A group of manufacturers in the same region faced similar challenges in sourcing capacitor protection equipment.

2. **Collaborative Strategies Employed**: They formed a consortium to pool their purchasing power, allowing them to negotiate better terms with suppliers.

3. **Results and Impact on Capacitor Protection**: The collaborative approach led to a 15% reduction in costs and improved access to high-quality equipment, demonstrating the effectiveness of shared procurement strategies.

VI. Challenges in Capacitor Protection Equipment Procurement

A. Supply Chain Disruptions

Global supply chain disruptions can impact the availability of capacitor protection equipment, leading to delays and increased costs.

B. Quality Assurance and Testing

Ensuring the quality of procured equipment is critical. Organizations must implement robust testing and quality assurance processes to mitigate risks.

C. Integration with Existing Systems

New equipment must integrate seamlessly with existing systems. Organizations must consider compatibility when procuring capacitor protection equipment.

D. Training and Skill Development for Procurement Teams

As procurement models evolve, so too must the skills of procurement teams. Ongoing training is essential to ensure teams can effectively navigate new technologies and processes.

VII. Future Trends in Capacitor Protection Equipment Procurement

A. Increased Automation and AI in Procurement Processes

Automation and artificial intelligence are set to revolutionize procurement processes, enhancing efficiency and decision-making.

B. Sustainability and Green Procurement Practices

As organizations prioritize sustainability, green procurement practices are becoming increasingly important. This trend will influence the types of capacitor protection equipment that organizations choose to procure.

C. The Role of Data Analytics in Decision-Making

Data analytics will play a crucial role in procurement decision-making, allowing organizations to make informed choices based on market trends and supplier performance.

D. Emerging Technologies and Their Impact on Procurement Models

Emerging technologies, such as blockchain and IoT, will further transform procurement models, enhancing transparency and efficiency.

VIII. Conclusion

In conclusion, the procurement of capacitor protection equipment is evolving rapidly, driven by technological advancements and changing market dynamics. Organizations must adapt their procurement models to meet these evolving needs, balancing cost, quality, and reliability. By understanding the latest procurement models and the factors influencing them, organizations can enhance their procurement strategies and ensure the continued reliability of their electrical systems.

IX. References

A comprehensive list of academic papers, industry reports, and relevant literature will provide further insights into procurement models and capacitor protection equipment. For those interested in exploring this topic further, additional resources are available to deepen understanding and inform best practices in procurement.