CORE_COMPETENCE

Product_Leaders

index_more

index_more_content

info_item01

info_item_content01

info_item02

info_item_content02

info_item03

info_item_content03

info_item04

info_item_content04

NEWS

NEWS

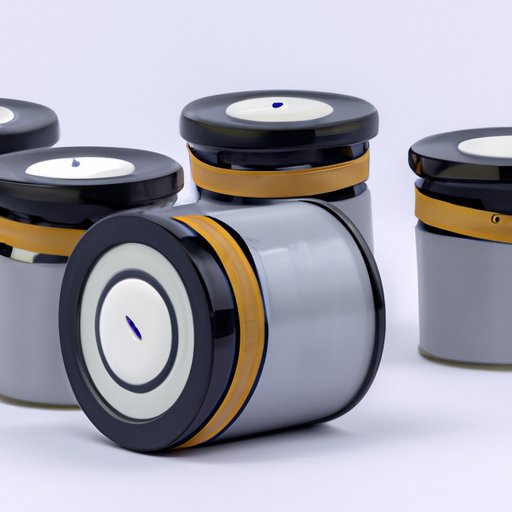

What is the production process of mainstream three-phase capacitors?

The Production Process of Mainstream Three-Phase Capacitors

I. Introduction

Three-phase capacitors are essential components in electrical systems, playing a crucial role in enhancing the efficiency and stability of power distribution. These capacitors are designed to improve power factor, stabilize voltage, and store energy, making them indispensable in various industrial and commercial applications. This blog post will delve into the production process of mainstream three-phase capacitors, exploring the materials used, the steps involved in manufacturing, and the importance of quality control.

II. Understanding Three-Phase Capacitors

A. Function and Applications

Three-phase capacitors serve multiple functions in electrical systems:

1. **Power Factor Correction**: They help improve the power factor in electrical systems, which is a measure of how effectively electrical power is being converted into useful work output. A higher power factor indicates more efficient use of electrical power, reducing energy costs and improving system reliability.

2. **Voltage Stabilization**: These capacitors stabilize voltage levels in power systems, ensuring that electrical equipment operates within safe voltage limits. This is particularly important in industrial settings where machinery requires consistent voltage for optimal performance.

3. **Energy Storage**: Three-phase capacitors can store energy temporarily, releasing it when needed to balance supply and demand in electrical systems. This capability is vital for applications such as renewable energy integration, where energy generation may not always align with consumption.

B. Types of Three-Phase Capacitors

There are several types of three-phase capacitors, each with unique characteristics:

1. **Film Capacitors**: These capacitors use thin plastic films as dielectric materials. They are known for their stability, low losses, and high insulation resistance, making them suitable for various applications.

2. **Electrolytic Capacitors**: Utilizing an electrolyte as one of the plates, these capacitors offer high capacitance values in a compact size. They are commonly used in power supply circuits but have limitations in terms of voltage and temperature stability.

3. **Ceramic Capacitors**: Made from ceramic materials, these capacitors are known for their high dielectric strength and stability over a wide temperature range. They are often used in high-frequency applications.

III. Raw Materials Used in Production

The production of three-phase capacitors involves several key raw materials:

A. Dielectric Materials

1. **Polypropylene**: This is a common dielectric material used in film capacitors due to its excellent electrical properties and thermal stability.

2. **Polyester**: Another popular dielectric, polyester is used for its good insulation properties and cost-effectiveness.

3. **Ceramic Materials**: Used in ceramic capacitors, these materials provide high dielectric strength and stability.

B. Conductive Materials

1. **Aluminum**: Often used for the plates in capacitors, aluminum is favored for its lightweight and conductive properties.

2. **Copper**: Known for its superior conductivity, copper is sometimes used in high-performance capacitors.

C. Insulating Materials

1. **Epoxy Resins**: These are used for encapsulating capacitors, providing excellent insulation and protection against environmental factors.

2. **Polyurethane**: Another insulating material, polyurethane is valued for its durability and resistance to moisture.

IV. The Production Process

The production of three-phase capacitors involves several critical steps:

A. Design and Engineering

The process begins with design and engineering, where specifications and requirements are established based on the intended application. Prototyping and testing are conducted to ensure that the design meets performance standards.

B. Material Preparation

Once the design is finalized, the next step is material preparation. This involves sourcing and conducting quality control on raw materials to ensure they meet industry standards. Dielectric films are then cut and shaped according to the specifications.

C. Assembly Process

The assembly process is where the capacitor begins to take shape:

1. **Layering Dielectric and Conductive Materials**: The dielectric material is layered with conductive materials, creating the capacitor's structure.

2. **Winding or Stacking Methods**: Depending on the type of capacitor being produced, the layers may be wound into a cylindrical shape or stacked in a rectangular configuration.

3. **Connection of Terminals**: After the layers are assembled, terminals are connected to facilitate electrical connections.

D. Encapsulation

Encapsulation is a crucial step in protecting the capacitor from environmental factors:

1. **Application of Insulating Materials**: Insulating materials, such as epoxy resins or polyurethane, are applied to the capacitor to provide protection.

2. **Sealing and Protection**: The encapsulated capacitor is sealed to prevent moisture ingress and other environmental damage.

E. Quality Control and Testing

Quality control is vital in ensuring the reliability and performance of three-phase capacitors:

1. **Electrical Testing**: Capacitors undergo electrical testing to verify capacitance values, voltage ratings, and other electrical characteristics.

2. **Mechanical Testing**: Mechanical tests, such as vibration and thermal cycling, are conducted to assess the durability and reliability of the capacitors under various conditions.

3. **Compliance with Industry Standards**: Capacitors must comply with industry standards, such as those set by the International Electrotechnical Commission (IEC) and Underwriters Laboratories (UL), to ensure safety and performance.

V. Finalization and Packaging

Once the capacitors pass quality control, they undergo final inspection and quality assurance. This step ensures that only products meeting the highest standards are packaged for distribution. Proper packaging is essential to protect the capacitors during transportation and storage. Additionally, documentation and labeling are provided to inform customers about the specifications and compliance of the product.

VI. Environmental Considerations

The production of three-phase capacitors also involves environmental considerations:

A. Waste Management During Production

Manufacturers must implement waste management practices to minimize the environmental impact of production. This includes recycling scrap materials and reducing waste generated during the manufacturing process.

B. Recycling of Materials

Recycling is an essential aspect of sustainability in capacitor production. Many materials used in capacitors, such as metals and plastics, can be recycled, reducing the demand for new raw materials and minimizing environmental impact.

C. Compliance with Environmental Regulations

Manufacturers must comply with environmental regulations to ensure that their production processes are sustainable and environmentally friendly. This includes adhering to regulations regarding hazardous materials and emissions.

VII. Conclusion

In summary, the production process of mainstream three-phase capacitors is a complex and meticulous endeavor that involves various stages, from design and material preparation to assembly and quality control. The significance of quality in three-phase capacitors cannot be overstated, as these components play a vital role in the efficiency and reliability of electrical systems. As technology advances, we can expect to see future trends in capacitor technology and production, including the development of new materials and manufacturing techniques that enhance performance and sustainability.

VIII. References

1. Academic journals on capacitor technology and materials science.

2. Industry reports on electrical components and manufacturing processes.

3. Standards and regulations documents from organizations such as IEC and UL.

This comprehensive overview of the production process of three-phase capacitors highlights the importance of these components in modern electrical systems and the intricate steps involved in their manufacturing. Understanding this process not only sheds light on the technology behind capacitors but also emphasizes the need for quality and sustainability in their production.

2025-03-06

0

What is the production process of mainstream filter capacitors?

The Production Process of Mainstream Filter Capacitors

I. Introduction

Filter capacitors are essential components in electronic circuits, playing a crucial role in smoothing out voltage fluctuations and ensuring stable power supply. These capacitors are designed to store and release electrical energy, filtering out unwanted signals and noise in various applications, from power supplies to audio equipment. Understanding the production process of filter capacitors is vital for appreciating their significance in modern electronics. This blog post will delve into the various types of filter capacitors, the raw materials used, the design and engineering processes, manufacturing steps, quality control measures, and future trends in the industry.

II. Types of Filter Capacitors

Filter capacitors come in several types, each with unique characteristics and applications:

A. Electrolytic Capacitors

Electrolytic capacitors are polarized capacitors that offer high capacitance values in a compact size. They are commonly used in power supply circuits due to their ability to handle large voltage fluctuations.

B. Ceramic Capacitors

Ceramic capacitors are non-polarized and known for their stability and reliability. They are widely used in high-frequency applications and are favored for their small size and low cost.

C. Film Capacitors

Film capacitors use a thin plastic film as the dielectric material. They are known for their excellent performance in audio applications and are often used in high-voltage circuits due to their robustness.

D. Tantalum Capacitors

Tantalum capacitors are known for their high capacitance-to-volume ratio and stability. They are often used in applications where space is limited, such as in mobile devices.

E. Comparison of Different Types

Each type of filter capacitor has its advantages and disadvantages, making them suitable for specific applications. For instance, while electrolytic capacitors are great for bulk energy storage, ceramic capacitors excel in high-frequency applications.

III. Raw Materials

A. Overview of Materials Used in Filter Capacitors

The production of filter capacitors requires various raw materials, primarily dielectric and conductive materials.

1. Dielectric Materials

Dielectric materials, such as aluminum oxide for electrolytic capacitors and ceramic materials for ceramic capacitors, are crucial for storing electrical energy.

2. Conductive Materials

Conductive materials, including aluminum and tantalum, are used for the capacitor plates, allowing for efficient energy transfer.

B. Sourcing and Quality Control of Raw Materials

Sourcing high-quality raw materials is essential for ensuring the performance and reliability of filter capacitors. Manufacturers often establish relationships with trusted suppliers and implement strict quality control measures to verify material integrity.

C. Environmental Considerations in Material Selection

With increasing awareness of environmental issues, manufacturers are now considering the ecological impact of their material choices. This includes selecting materials that are recyclable or have a lower environmental footprint.

IV. Design and Engineering

A. Initial Design Considerations

The design of filter capacitors begins with several key considerations:

1. Capacitance Value

The required capacitance value is determined based on the specific application and performance requirements.

2. Voltage Rating

The voltage rating is critical to ensure that the capacitor can handle the maximum voltage it will encounter in operation.

3. Temperature Stability

Temperature stability is essential for maintaining performance across varying environmental conditions.

B. Simulation and Modeling

Before moving to production, engineers use simulation software to model the capacitor's performance under different conditions. This helps identify potential issues and optimize the design.

C. Prototyping and Testing

Once the design is finalized, prototypes are created and subjected to rigorous testing to ensure they meet the required specifications.

V. Manufacturing Process

The manufacturing process of filter capacitors involves several key steps:

A. Step 1: Preparation of Materials

The first step involves preparing the dielectric and conductive materials. For instance, dielectric films are produced through processes like extrusion or casting, while electrolytes for electrolytic capacitors are prepared using specific chemical formulations.

B. Step 2: Assembly of Capacitor Components

In this step, the capacitor components are assembled. This may involve layering dielectric and conductive materials, followed by winding or stacking them to form the capacitor structure.

C. Step 3: Encapsulation and Sealing

Once assembled, the capacitors are encapsulated to protect them from environmental factors. Different encapsulation methods, such as resin or plastic casing, are used depending on the capacitor type. Proper sealing is crucial for ensuring longevity and reliability.

D. Step 4: Electrical Testing and Quality Assurance

After encapsulation, each capacitor undergoes electrical testing to verify its capacitance, equivalent series resistance (ESR), and leakage current. Compliance with industry standards is also checked to ensure quality.

VI. Quality Control Measures

Quality control is a critical aspect of capacitor production:

A. In-Process Quality Checks

Manufacturers implement in-process quality checks at various stages of production to identify and rectify issues early.

B. Final Inspection and Testing

Before packaging, each capacitor undergoes a final inspection and testing phase to ensure it meets all specifications.

C. Certification and Compliance with International Standards

Manufacturers often seek certification from international standards organizations, such as ISO and RoHS, to demonstrate their commitment to quality and environmental responsibility.

VII. Packaging and Distribution

A. Packaging Methods for Protection During Transport

Proper packaging is essential to protect capacitors during transport. Manufacturers use anti-static materials and cushioning to prevent damage.

B. Distribution Channels and Logistics

Capacitors are distributed through various channels, including direct sales, distributors, and online platforms. Efficient logistics are crucial for timely delivery.

C. Importance of Proper Labeling and Documentation

Accurate labeling and documentation are vital for ensuring that customers receive the correct products and understand their specifications.

VIII. Environmental and Regulatory Considerations

A. Impact of Capacitor Production on the Environment

The production of filter capacitors can have environmental impacts, including waste generation and energy consumption. Manufacturers are increasingly focused on minimizing these effects.

B. Regulations Governing Capacitor Manufacturing

Various regulations govern capacitor manufacturing, including those related to hazardous materials and waste management. Compliance is essential for legal operation.

C. Sustainable Practices in the Production Process

Many manufacturers are adopting sustainable practices, such as using renewable energy sources and recycling materials, to reduce their environmental footprint.

IX. Future Trends in Filter Capacitor Production

A. Innovations in Materials and Technology

The capacitor industry is witnessing innovations in materials, such as the development of new dielectric materials that enhance performance and reduce size.

B. The Role of Automation and AI in Manufacturing

Automation and artificial intelligence are increasingly being integrated into the manufacturing process, improving efficiency and reducing human error.

C. Market Trends and Consumer Demands

As technology advances, consumer demands for smaller, more efficient capacitors are driving the industry towards continuous improvement and innovation.

X. Conclusion

The production process of mainstream filter capacitors is a complex and multifaceted endeavor that requires careful consideration of materials, design, manufacturing, and quality control. As technology continues to evolve, the importance of high-quality filter capacitors in electronic circuits cannot be overstated. The industry is poised for growth, driven by innovations in materials and manufacturing processes, as well as a commitment to sustainability and environmental responsibility. Understanding this production process not only highlights the significance of filter capacitors but also underscores the ongoing advancements that will shape the future of electronics.

XI. References

- Academic journals and articles on capacitor technology

- Industry reports and white papers on electronic components

- Manufacturer guidelines and standards for capacitor production

This comprehensive overview of the production process of mainstream filter capacitors provides valuable insights into the complexities and innovations within the industry, ensuring a deeper understanding of these essential electronic components.

2025-03-05

0

What are the important product categories of capacitors?

Important Product Categories of Capacitors

I. Introduction

Capacitors are fundamental components in electronic circuits, playing a crucial role in energy storage, filtering, and signal processing. They are passive electrical devices that store electrical energy in an electric field, allowing them to perform various functions in a circuit. This blog post aims to explore the important product categories of capacitors, highlighting their characteristics, applications, and significance in modern electronics.

II. Basic Principles of Capacitors

A. How Capacitors Work

Capacitors operate on the principle of storing electrical energy. When a voltage is applied across the terminals of a capacitor, an electric field is created between its plates, allowing it to store energy. The amount of energy a capacitor can store is determined by its capacitance, which is measured in farads (F). Capacitance is influenced by the surface area of the plates, the distance between them, and the type of dielectric material used.

B. Key Components of Capacitors

1. **Dielectric Materials**: The dielectric is an insulating material placed between the plates of a capacitor. It increases the capacitor's ability to store charge by reducing the electric field strength between the plates. Common dielectric materials include ceramic, plastic, and electrolytic substances.

2. **Plates and Their Configuration**: Capacitors consist of two conductive plates separated by the dielectric. The configuration of these plates can vary, affecting the capacitor's performance and application. For instance, rolled or stacked configurations can enhance capacitance in certain designs.

III. Major Product Categories of Capacitors

A. Ceramic Capacitors

Ceramic capacitors are among the most widely used capacitors in electronic circuits. They are made from ceramic materials and are known for their stability and reliability.

1. **Characteristics and Applications**: Ceramic capacitors are available in various capacitance values and voltage ratings. They are commonly used in decoupling, filtering, and timing applications.

2. **Types of Ceramic Capacitors**: There are two main classes of ceramic capacitors: Class 1 (temperature-stable) and Class 2 (high-capacitance). Class 1 capacitors are used in precision applications, while Class 2 capacitors are favored for general-purpose use.

3. **Advantages and Disadvantages**: Ceramic capacitors are compact, have low equivalent series resistance (ESR), and are cost-effective. However, they can exhibit capacitance variation with voltage and temperature, which may limit their use in certain applications.

B. Electrolytic Capacitors

Electrolytic capacitors are polarized capacitors that use an electrolyte as one of their plates. They are known for their high capacitance values.

1. **Overview and Construction**: These capacitors consist of a metal oxide layer that acts as the dielectric, with an electrolyte solution providing the second plate.

2. **Types**: The most common types are aluminum and tantalum electrolytic capacitors. Aluminum capacitors are widely used in power supply circuits, while tantalum capacitors are preferred for their stability and reliability in compact designs.

3. **Applications and Limitations**: Electrolytic capacitors are used in power supply filtering, audio applications, and energy storage. However, they have a limited lifespan and can fail if subjected to reverse polarity.

C. Film Capacitors

Film capacitors are made from thin plastic films as the dielectric material. They are known for their excellent performance and reliability.

1. **Description and Types**: Common types of film capacitors include polyester, polypropylene, and polystyrene. Each type has unique characteristics that make it suitable for specific applications.

2. **Benefits and Typical Uses**: Film capacitors offer low ESR, high insulation resistance, and stability over a wide temperature range. They are commonly used in audio circuits, power electronics, and timing applications.

3. **Comparison with Other Capacitor Types**: Compared to electrolytic capacitors, film capacitors have a longer lifespan and better performance in high-frequency applications.

D. Tantalum Capacitors

Tantalum capacitors are a type of electrolytic capacitor that uses tantalum metal for the anode. They are known for their high capacitance and reliability.

1. **Unique Properties and Construction**: Tantalum capacitors have a very thin oxide layer that serves as the dielectric, allowing for high capacitance in a small package.

2. **Applications in Modern Electronics**: They are widely used in portable electronics, medical devices, and aerospace applications due to their stability and reliability.

3. **Advantages and Potential Drawbacks**: Tantalum capacitors offer excellent performance and reliability but can be expensive and sensitive to voltage spikes.

E. Supercapacitors (Ultracapacitors)

Supercapacitors, also known as ultracapacitors, are energy storage devices that bridge the gap between traditional capacitors and batteries.

1. **Definition and Working Principle**: Supercapacitors store energy through electrostatic charge separation, allowing them to deliver high power quickly.

2. **Applications in Energy Storage and Power Delivery**: They are used in applications requiring rapid charge and discharge cycles, such as regenerative braking systems in electric vehicles and backup power supplies.

3. **Comparison with Traditional Capacitors**: Supercapacitors have much higher capacitance values than traditional capacitors, making them suitable for energy storage applications.

F. Mica Capacitors

Mica capacitors are known for their stability and precision, making them ideal for high-frequency applications.

1. **Characteristics and Construction**: These capacitors use mica as the dielectric material, providing excellent thermal stability and low loss.

2. **Applications in High-Frequency Circuits**: Mica capacitors are commonly used in RF applications, oscillators, and filters.

3. **Advantages and Disadvantages**: They offer high precision and stability but can be more expensive than other capacitor types.

G. Paper Capacitors

Paper capacitors, once widely used, have become less common but still find applications in specific areas.

1. **Overview and Historical Context**: These capacitors use paper as the dielectric material, often impregnated with oil for improved performance.

2. **Current Applications and Relevance**: They are still used in audio applications and vintage electronics.

3. **Pros and Cons**: While they offer good performance, paper capacitors can be bulky and less reliable than modern alternatives.

IV. Specialized Capacitors

A. High-Voltage Capacitors

High-voltage capacitors are designed to operate at elevated voltage levels, making them essential in power systems.

1. **Applications in Power Systems**: They are used in power transmission, energy storage, and power factor correction.

2. **Design Considerations and Materials Used**: These capacitors are constructed with materials that can withstand high voltages and are often larger in size.

B. RF Capacitors

RF capacitors are specialized for radio frequency applications, where performance at high frequencies is critical.

1. **Importance in Radio Frequency Applications**: They are used in RF amplifiers, oscillators, and filters.

2. **Characteristics and Types**: RF capacitors are designed to minimize losses and maintain performance at high frequencies.

C. Motor Run and Motor Start Capacitors

Motor run and motor start capacitors are essential components in electric motors.

1. **Role in Electric Motors**: Motor run capacitors help maintain the motor's operation, while motor start capacitors provide the initial boost needed to start the motor.

2. **Differences Between Run and Start Capacitors**: Run capacitors are designed for continuous operation, while start capacitors are used for short bursts of energy.

V. Factors Influencing Capacitor Selection

When selecting a capacitor for a specific application, several factors must be considered:

1. **Capacitance Value and Tolerance**: The required capacitance value and acceptable tolerance levels are critical for circuit performance.

2. **Voltage Rating**: The capacitor must be rated for the maximum voltage it will encounter in the circuit.

3. **Temperature Coefficient**: The capacitor's performance can vary with temperature, so the temperature coefficient should match the application requirements.

4. **Size and Form Factor**: The physical size and shape of the capacitor can impact its suitability for specific designs.

5. **Application-Specific Requirements**: Certain applications may have unique requirements, such as low ESR or high-frequency performance.

VI. Future Trends in Capacitor Technology

The capacitor industry is evolving, driven by advancements in materials and design:

1. **Innovations in Materials and Design**: New dielectric materials and manufacturing techniques are improving capacitor performance and reliability.

2. **The Impact of Electric Vehicles and Renewable Energy**: The growing demand for energy storage solutions in electric vehicles and renewable energy systems is driving innovation in capacitor technology.

3. **Miniaturization and Integration in Modern Electronics**: As electronic devices become smaller and more complex, capacitors are being designed for integration into compact circuits.

VII. Conclusion

Capacitors are essential components in modern electronics, with various product categories tailored to meet specific needs. From ceramic and electrolytic capacitors to supercapacitors and specialized types, each category offers unique characteristics and applications. As technology continues to advance, capacitors will play a vital role in shaping the future of electronic devices and systems.

VIII. References

For further exploration of capacitors and their applications, consider the following resources:

1. "Capacitors: Principles and Applications" by John Smith

2. IEEE Standards for Capacitors

3. Manufacturer datasheets and technical specifications for various capacitor types

By understanding the different product categories of capacitors, engineers and designers can make informed decisions that enhance the performance and reliability of their electronic circuits.

2025-03-04

0