What is the Market Prospect of Strip Resistors?

I. Introduction

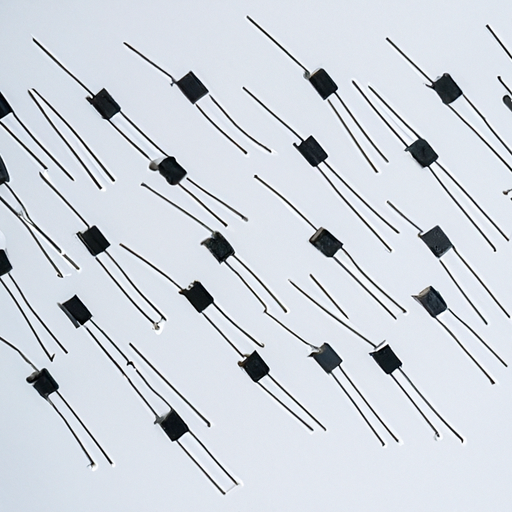

In the realm of electronics, strip resistors play a crucial role in ensuring the proper functioning of various devices. Defined as resistive components that are typically flat and elongated, strip resistors are designed to provide precise resistance values in a compact form factor. Their importance cannot be overstated, as they are integral to a wide range of applications, from industrial machinery to consumer electronics. As the demand for electronic devices continues to surge, understanding the market landscape for strip resistors becomes essential for manufacturers, investors, and consumers alike.

II. Types of Strip Resistors

Strip resistors come in several types, each with unique characteristics and applications.

A. Carbon Strip Resistors

Carbon strip resistors are made from a carbon composition, which provides a cost-effective solution for many applications. They are known for their stability and reliability, making them suitable for general-purpose use. However, they may not perform as well under high temperatures or in precision applications.

B. Metal Film Strip Resistors

Metal film strip resistors offer superior accuracy and stability compared to their carbon counterparts. They are constructed from a thin layer of metal, which allows for tighter tolerances and better temperature coefficients. This makes them ideal for applications requiring high precision, such as in medical devices and high-end audio equipment.

C. Wire-Wound Strip Resistors

Wire-wound strip resistors are made by winding a metal wire around a ceramic or plastic core. They are known for their high power handling capabilities and are often used in power electronics and industrial applications. However, they can be bulkier and more expensive than other types.

D. Comparison of Different Types

When comparing these types, it is essential to consider factors such as cost, precision, temperature stability, and power handling capabilities. While carbon strip resistors may be suitable for low-cost applications, metal film and wire-wound resistors are preferred in high-performance scenarios.

III. Applications of Strip Resistors

The versatility of strip resistors allows them to be utilized across various sectors.

A. Industrial Applications

1. Power Electronics

In power electronics, strip resistors are used for current sensing and voltage division. Their ability to handle high power levels makes them indispensable in applications such as inverters and converters.

2. Automation Systems

Automation systems rely on strip resistors for feedback and control mechanisms. They help ensure that systems operate within specified parameters, enhancing efficiency and safety.

B. Consumer Electronics

1. Audio Equipment

In the audio industry, strip resistors are used in amplifiers and equalizers to manage signal levels and improve sound quality. Their precision is crucial for delivering high-fidelity audio experiences.

2. Home Appliances

From washing machines to microwaves, strip resistors are found in various home appliances, where they help regulate power and ensure safe operation.

C. Automotive Applications

1. Electric Vehicles

With the rise of electric vehicles (EVs), strip resistors are increasingly used in battery management systems and regenerative braking systems. Their reliability is vital for the performance and safety of EVs.

2. Advanced Driver-Assistance Systems (ADAS)

ADAS technologies, which enhance vehicle safety and automation, utilize strip resistors for sensor calibration and data processing, ensuring accurate readings and responses.

D. Telecommunications

1. Signal Processing

In telecommunications, strip resistors are essential for signal processing applications, where they help manage and filter signals to maintain clarity and integrity.

2. Network Equipment

Network equipment, such as routers and switches, also employs strip resistors to ensure stable performance and efficient data transmission.

IV. Market Trends and Drivers

The market for strip resistors is influenced by several key trends and drivers.

A. Growing Demand for Electronic Devices

As the global population becomes increasingly reliant on electronic devices, the demand for components like strip resistors is expected to rise. This trend is particularly evident in emerging markets, where access to technology is expanding rapidly.

B. Advancements in Technology

1. Miniaturization of Components

The trend towards miniaturization in electronics is driving the development of smaller, more efficient strip resistors. Manufacturers are innovating to create components that can fit into increasingly compact devices without sacrificing performance.

2. Increased Efficiency and Performance

As industries strive for greater efficiency, the demand for high-performance strip resistors is growing. Innovations in materials and manufacturing processes are enabling the production of resistors that can operate at higher temperatures and with greater precision.

C. Shift Towards Renewable Energy Sources

The global shift towards renewable energy is impacting power management systems, where strip resistors play a critical role. As more industries adopt sustainable practices, the need for reliable resistive components in energy systems will continue to grow.

D. Rise of Electric Vehicles and Smart Technologies

The automotive industry's transition to electric vehicles and the proliferation of smart technologies are significant drivers for the strip resistor market. These sectors require advanced components that can meet the demands of modern applications.

V. Challenges Facing the Strip Resistor Market

Despite the positive outlook, the strip resistor market faces several challenges.

A. Competition from Alternative Technologies

As technology evolves, alternative solutions such as digital resistors and programmable devices are emerging. These alternatives may offer advantages in certain applications, posing a challenge to traditional strip resistors.

B. Supply Chain Disruptions

Recent global events have highlighted vulnerabilities in supply chains, affecting the availability of raw materials needed for resistor production. Manufacturers must navigate these challenges to maintain production levels.

C. Regulatory Challenges

The electronics industry is subject to stringent regulations regarding safety and environmental impact. Compliance with these regulations can be a barrier to entry for new manufacturers and may increase costs for existing players.

D. Price Volatility of Raw Materials

The prices of raw materials used in the production of strip resistors can be volatile, impacting profit margins and pricing strategies. Manufacturers must develop strategies to mitigate these risks.

VI. Regional Market Analysis

The market for strip resistors varies significantly across different regions.

A. North America

1. Market Size and Growth Potential

North America is a mature market for strip resistors, with steady growth driven by advancements in technology and increasing demand for electronic devices.

2. Key Players and Innovations

Key players in the North American market are focusing on innovation and product development to maintain competitiveness. Collaborations with tech companies are also on the rise.

B. Europe

1. Regulatory Environment

Europe's regulatory environment is stringent, particularly concerning environmental sustainability. Manufacturers must adapt to these regulations to succeed in this market.

2. Focus on Sustainability

The European market is increasingly focused on sustainable practices, driving demand for eco-friendly strip resistors and components.

C. Asia-Pacific

1. Manufacturing Hub

The Asia-Pacific region is a global manufacturing hub for electronic components, including strip resistors. The region's cost advantages and skilled workforce contribute to its dominance in production.

2. Rapid Industrialization and Urbanization

Rapid industrialization and urbanization in countries like China and India are driving demand for electronic devices, subsequently boosting the strip resistor market.

D. Latin America and Middle East

1. Emerging Markets

Latin America and the Middle East present emerging markets for strip resistors, with increasing investments in technology and infrastructure.

2. Investment Opportunities

As these regions develop, there are significant investment opportunities for manufacturers looking to expand their presence in the strip resistor market.

VII. Future Outlook

The future of the strip resistor market appears promising, with several factors contributing to growth.

A. Predictions for Market Growth

Market analysts predict steady growth in the strip resistor market over the next decade, driven by the increasing demand for electronic devices and advancements in technology.

B. Innovations on the Horizon

Innovations in materials and manufacturing processes are expected to enhance the performance and efficiency of strip resistors, making them more competitive in the market.

C. Strategic Recommendations for Stakeholders

Stakeholders in the strip resistor market should focus on innovation, sustainability, and strategic partnerships to navigate challenges and capitalize on growth opportunities.

VIII. Conclusion

In summary, the market prospects for strip resistors are robust, driven by growing demand across various sectors, technological advancements, and the shift towards renewable energy. While challenges exist, the opportunities for innovation and growth are significant. As the electronics industry continues to evolve, strip resistors will remain a vital component, ensuring the reliability and performance of countless devices. Stakeholders who adapt to market trends and invest in innovation will be well-positioned to thrive in this dynamic landscape.