What are the Main Application Directions of Power Wirewound Resistors?

I. Introduction

In the realm of electronics, resistors play a crucial role in controlling current flow and managing voltage levels. Among the various types of resistors, power wirewound resistors stand out due to their unique construction and superior performance characteristics. These resistors are made by winding a wire around a core, which allows them to handle higher power levels compared to other resistor types. This blog post will explore the main application directions of power wirewound resistors, highlighting their significance across various industries.

II. Characteristics of Power Wirewound Resistors

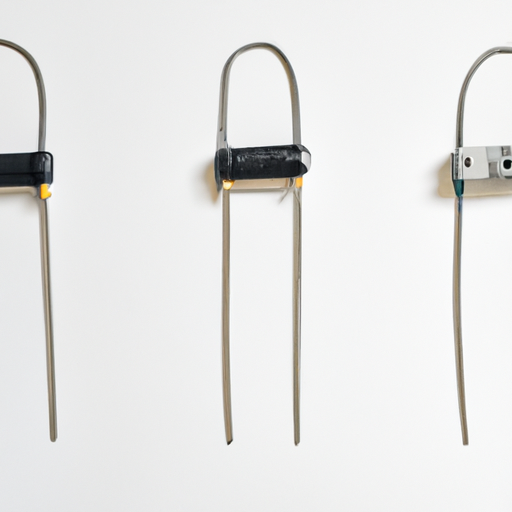

A. Construction and Materials

Power wirewound resistors are constructed using a wire, typically made from materials such as nickel-chromium or copper-nickel, which is wound around a ceramic or metal core. This design not only provides excellent thermal conductivity but also allows for a compact form factor, making them suitable for high-power applications.

B. Key Specifications

1. **Power Rating**: Power wirewound resistors are designed to handle significant power levels, often ranging from a few watts to several kilowatts. This capability makes them ideal for applications where high power dissipation is required.

2. **Resistance Range**: These resistors are available in a wide range of resistance values, typically from a few ohms to several megaohms, allowing for versatility in circuit design.

3. **Tolerance and Temperature Coefficient**: Power wirewound resistors generally offer tight tolerances (often ±1% or better) and low temperature coefficients, ensuring stable performance across varying environmental conditions.

C. Advantages Over Other Resistor Types

Power wirewound resistors provide several advantages over other resistor types, including:

1. **High Power Handling**: Their construction allows them to dissipate heat effectively, making them suitable for high-power applications.

2. **Stability and Reliability**: Wirewound resistors exhibit excellent stability over time, with minimal drift in resistance values, which is critical for precision applications.

3. **Low Noise Characteristics**: These resistors produce less electrical noise compared to carbon or metal film resistors, making them ideal for sensitive electronic circuits.

III. Main Application Directions

A. Industrial Applications

Power wirewound resistors are widely used in industrial settings, where their high power handling capabilities are essential. Some key applications include:

1. **Power Supplies and Converters**: In power supply units, wirewound resistors are used for voltage division, current sensing, and load testing, ensuring stable operation under varying loads.

2. **Motor Control Systems**: These resistors are integral to motor control circuits, providing feedback and ensuring precise control of motor speed and torque.

3. **Load Banks and Testing Equipment**: In testing environments, wirewound resistors are used to simulate loads, allowing engineers to evaluate the performance of power systems and components.

B. Automotive Applications

The automotive industry has seen a significant shift towards electric and hybrid vehicles, where power wirewound resistors play a vital role:

1. **Electric and Hybrid Vehicles**: These resistors are used in battery management systems to monitor and control battery performance, ensuring efficient energy use and prolonging battery life.

2. **Battery Management Systems**: Power wirewound resistors help in balancing the charge across battery cells, preventing overheating and enhancing safety.

3. **Anti-lock Braking Systems (ABS)**: In ABS, wirewound resistors are used for signal processing and feedback control, ensuring optimal braking performance.

C. Telecommunications

In the telecommunications sector, power wirewound resistors are essential for maintaining signal integrity and system reliability:

1. **Signal Processing Equipment**: These resistors are used in various signal processing applications, including amplifiers and filters, where precision and stability are paramount.

2. **Base Stations and Repeaters**: Power wirewound resistors are employed in base stations to manage power levels and ensure consistent signal transmission.

3. **Network Infrastructure**: In networking equipment, these resistors help regulate power and protect sensitive components from voltage spikes.

D. Consumer Electronics

Power wirewound resistors are also prevalent in consumer electronics, where they contribute to performance and reliability:

1. **Audio Equipment**: In high-fidelity audio systems, wirewound resistors are used in crossover networks and amplifiers, providing low distortion and high stability.

2. **Home Appliances**: These resistors are found in various home appliances, such as washing machines and microwaves, where they help manage power and ensure safe operation.

3. **Gaming Consoles**: In gaming consoles, power wirewound resistors are used in power supply circuits, ensuring stable performance during intense gaming sessions.

E. Medical Devices

The medical field relies heavily on precision and reliability, making power wirewound resistors indispensable in various applications:

1. **Diagnostic Equipment**: In devices such as MRI machines and ultrasound equipment, these resistors help maintain accurate readings and stable operation.

2. **Imaging Systems**: Power wirewound resistors are used in imaging systems to manage power levels and ensure consistent performance.

3. **Patient Monitoring Systems**: In patient monitoring devices, these resistors help regulate power and ensure accurate data transmission.

IV. Emerging Trends and Innovations

As technology advances, the applications of power wirewound resistors continue to evolve. Some emerging trends include:

A. Miniaturization and Integration

With the push for smaller and more efficient electronic devices, manufacturers are focusing on miniaturizing power wirewound resistors without compromising performance. This trend allows for greater integration of components in compact designs.

B. Enhanced Thermal Management Techniques

Innovations in thermal management are crucial for improving the performance and longevity of power wirewound resistors. Advanced materials and designs are being developed to enhance heat dissipation, ensuring reliable operation in high-power applications.

C. Smart Resistors and IoT Applications

The rise of the Internet of Things (IoT) has led to the development of smart resistors that can communicate data about their performance and condition. These resistors can provide real-time feedback, enabling predictive maintenance and enhancing system reliability.

D. Sustainability and Eco-friendly Materials

As industries move towards more sustainable practices, there is a growing emphasis on using eco-friendly materials in the production of power wirewound resistors. This shift not only reduces environmental impact but also meets the increasing demand for sustainable electronics.

V. Conclusion

Power wirewound resistors are integral components in a wide range of applications, from industrial machinery to consumer electronics and medical devices. Their unique characteristics, including high power handling, stability, and low noise, make them indispensable in modern electronic circuits. As technology continues to advance, the future of power wirewound resistors looks promising, with emerging trends such as miniaturization, enhanced thermal management, and smart technology paving the way for new applications. In conclusion, power wirewound resistors will continue to play a vital role in shaping the future of electronics, ensuring reliability and performance across various industries.