Manufacturing Processes of the Latest Porcelain Tube Resistors

I. Introduction

Porcelain tube resistors are essential components in electronic circuits, providing resistance to the flow of electric current. These resistors are known for their durability, stability, and ability to handle high power levels, making them a preferred choice in various applications. Over the years, the evolution of porcelain tube resistors has seen significant advancements in materials, design, and manufacturing processes, leading to improved performance and reliability.

II. Materials Used in Porcelain Tube Resistors

A. Composition of Porcelain

The primary material used in porcelain tube resistors is porcelain itself, which is a ceramic material made from a mixture of several key components:

1. **Clay**: This is the main ingredient that provides plasticity to the mixture, allowing it to be shaped easily during the manufacturing process.

2. **Feldspar**: This mineral acts as a flux, lowering the melting point of the mixture and helping to form a glassy phase during firing, which enhances the strength and durability of the final product.

3. **Quartz**: This component adds rigidity and thermal stability to the porcelain, ensuring that the resistors can withstand high temperatures without deforming.

B. Conductive Materials

To create the resistance element within the porcelain tube, various conductive materials are used:

1. **Carbon**: Often used in the form of carbon black, this material provides a stable and reliable resistance.

2. **Metal Oxides**: These materials, such as tin oxide or indium oxide, can also be used to create resistive elements with specific resistance values and temperature coefficients.

C. Insulating Materials

To ensure that the resistors function effectively, insulating materials are applied:

1. **Glazes**: A glassy coating that provides electrical insulation and enhances the aesthetic appeal of the resistor.

2. **Other Insulating Compounds**: These may include various ceramic materials that further improve the insulation properties of the resistor.

III. Design Considerations

A. Electrical Specifications

When designing porcelain tube resistors, several electrical specifications must be considered:

1. **Resistance Values**: The desired resistance is determined based on the application requirements.

2. **Power Ratings**: The resistor must be able to handle the power levels it will encounter in its intended use.

B. Physical Dimensions

The physical dimensions of the resistor are also crucial:

1. **Tube Length and Diameter**: These dimensions affect the resistance value and power handling capabilities.

2. **Terminal Configurations**: The design of the terminals must accommodate the intended connections in the circuit.

C. Aesthetic Factors

In addition to functionality, aesthetic considerations play a role in the design:

1. **Color and Finish**: The appearance of the resistor can be important for branding and integration into electronic devices.

2. **Branding and Labeling**: Clear labeling of specifications and branding enhances product recognition and compliance.

IV. Manufacturing Processes

A. Material Preparation

The manufacturing process begins with material preparation:

1. **Sourcing Raw Materials**: High-quality raw materials are sourced from reliable suppliers to ensure consistent performance.

2. **Mixing and Milling**: The raw materials are mixed and milled to achieve a uniform consistency, which is critical for the subsequent shaping process.

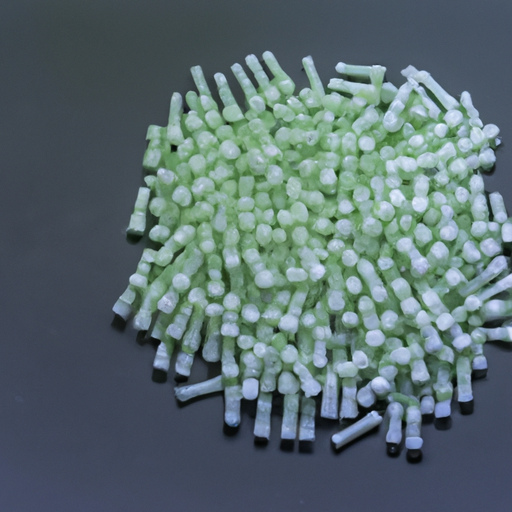

B. Shaping the Porcelain

The next step involves shaping the porcelain:

1. **Forming Techniques**:

- **Extrusion**: This method involves forcing the mixed material through a die to create long tubes of the desired diameter.

- **Molding**: Alternatively, the material can be pressed into molds to create specific shapes and sizes.

2. **Drying Processes**: After shaping, the porcelain is dried to remove excess moisture, preparing it for firing.

C. Firing the Porcelain

Firing is a crucial step in the manufacturing process:

1. **Initial Bisque Firing**: The shaped porcelain is fired at a lower temperature to harden it and remove any remaining moisture.

2. **Glazing and Second Firing**: After glazing, a second firing at a higher temperature is performed to fuse the glaze and enhance the strength and insulation properties of the resistor.

D. Adding Resistance Elements

Once the porcelain is prepared, the resistance elements are added:

1. **Application of Conductive Materials**: The conductive materials are applied to the surface of the porcelain tube, either through printing or coating techniques.

2. **Integration of Resistive Elements**: The resistive elements are integrated into the design, ensuring they are securely attached and properly positioned.

E. Final Assembly

The final assembly process includes:

1. **Attaching Terminals**: Terminals are attached to the resistor, allowing for easy integration into electronic circuits.

2. **Quality Control Checks**: Rigorous quality control checks are performed to ensure that each resistor meets the specified standards.

V. Quality Assurance and Testing

Quality assurance is critical in the manufacturing of porcelain tube resistors:

A. Electrical Testing

1. **Resistance Measurement**: Each resistor is tested to ensure it meets the specified resistance values.

2. **Power Handling Tests**: Resistors are subjected to power handling tests to verify their performance under load.

B. Mechanical Testing

1. **Durability Assessments**: Mechanical tests are conducted to evaluate the physical robustness of the resistors.

2. **Thermal Stability Tests**: These tests ensure that the resistors can withstand temperature fluctuations without failure.

C. Compliance with Industry Standards

1. **ISO Certifications**: Manufacturers often seek ISO certifications to demonstrate their commitment to quality.

2. **RoHS Compliance**: Compliance with the Restriction of Hazardous Substances (RoHS) directive ensures that the resistors are free from harmful materials.

VI. Innovations in Porcelain Tube Resistor Manufacturing

A. Advances in Materials Science

Recent innovations have led to improvements in materials used in porcelain tube resistors:

1. **Improved Conductive Materials**: New formulations of conductive materials enhance performance and reliability.

2. **Enhanced Insulating Properties**: Advances in insulating materials contribute to better thermal and electrical performance.

B. Automation and Technology in Manufacturing

The manufacturing process has also benefited from technological advancements:

1. **Robotics in Production**: Automation through robotics has increased efficiency and precision in the manufacturing process.

2. **Computer-Aided Design (CAD) Applications**: CAD technology allows for more complex designs and better optimization of resistor performance.

C. Environmental Considerations

Manufacturers are increasingly focusing on sustainability:

1. **Sustainable Sourcing of Materials**: Efforts are being made to source materials responsibly and sustainably.

2. **Waste Reduction Techniques**: Innovative manufacturing processes aim to minimize waste and reduce the environmental impact.

VII. Applications of Porcelain Tube Resistors

Porcelain tube resistors are used in a variety of applications:

A. Use in High-Power Applications

These resistors are ideal for high-power applications, such as power supplies and industrial machinery, where reliability is critical.

B. Role in Audio Equipment

In audio equipment, porcelain tube resistors are valued for their stability and low noise characteristics, contributing to high-quality sound reproduction.

C. Applications in Industrial Settings

They are commonly used in industrial settings for controlling current and voltage in various machinery and equipment.

D. Emerging Uses in Renewable Energy Systems

With the rise of renewable energy systems, porcelain tube resistors are finding new applications in solar inverters and wind turbine controllers, where efficiency and reliability are paramount.

VIII. Conclusion

The manufacturing processes of porcelain tube resistors have evolved significantly, driven by advancements in materials science, technology, and design. As the demand for reliable and efficient electronic components continues to grow, ongoing innovation in the field will be essential. The future of porcelain tube resistors looks promising, with potential developments in performance, sustainability, and application versatility.

IX. References

- Academic journals on materials science and electronics.

- Industry publications detailing advancements in resistor technology.

- Manufacturer specifications and guidelines for porcelain tube resistors.

This comprehensive overview of the manufacturing processes of porcelain tube resistors highlights the intricate steps involved in creating these essential components, showcasing the blend of traditional craftsmanship and modern technology that defines their production.