What are the Product Features of Automotive Resistors?

I. Introduction

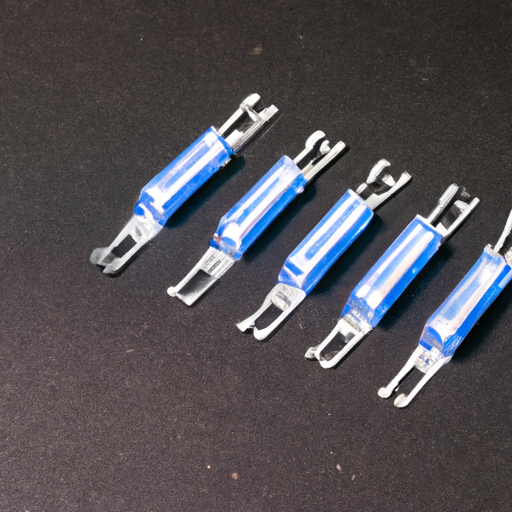

Automotive resistors are essential components in modern vehicles, playing a critical role in various electrical and electronic systems. These components help regulate current flow, manage voltage levels, and ensure the proper functioning of numerous automotive applications. As vehicles become increasingly sophisticated, understanding the features and functions of automotive resistors is vital for engineers, manufacturers, and automotive enthusiasts alike. This article will explore the different types of automotive resistors, their key features, material composition, environmental considerations, applications, and emerging trends in the industry.

II. Types of Automotive Resistors

A. Fixed Resistors

Fixed resistors are the most common type of resistors used in automotive applications. They have a predetermined resistance value that does not change. These resistors are crucial for controlling current flow in various circuits, ensuring that components receive the appropriate voltage and current levels. Common applications of fixed resistors in vehicles include:

Voltage dividers: Used to reduce voltage levels for sensors and other components.

Current limiting: Protecting sensitive components from excessive current.

Pull-up and pull-down resistors: Ensuring stable logic levels in digital circuits.

B. Variable Resistors (Potentiometers)

Variable resistors, or potentiometers, allow for adjustable resistance values. This flexibility makes them ideal for applications where fine-tuning is necessary. In automotive systems, potentiometers are commonly used in:

Throttle position sensors: Adjusting the resistance based on the position of the throttle.

Volume controls: In infotainment systems, allowing users to adjust sound levels.

Climate control systems: Enabling users to set desired temperature levels.

C. Specialty Resistors

Specialty resistors are designed for specific applications and often have unique characteristics. Examples include:

Thermistors: Temperature-sensitive resistors used in engine management systems to monitor coolant temperature.

Photoresistors: Light-sensitive resistors used in automatic lighting systems, such as headlights that adjust based on ambient light conditions.

III. Key Features of Automotive Resistors

A. Resistance Value

The resistance value of a resistor, measured in Ohms, is a fundamental characteristic that determines how much current will flow through a circuit. In automotive applications, selecting the correct resistance value is crucial for ensuring that components operate within their specified limits. Incorrect resistance values can lead to circuit malfunctions, component damage, or even safety hazards.

B. Power Rating

The power rating of a resistor indicates the maximum amount of power it can dissipate without overheating. This rating is essential for ensuring the reliability and safety of automotive circuits. Resistors with inadequate power ratings may fail, leading to circuit failures or fires. Understanding the power requirements of a circuit is vital for selecting the appropriate resistor.

C. Tolerance

Tolerance refers to the allowable variation in a resistor's resistance value. It is typically expressed as a percentage. For example, a resistor with a tolerance of ±5% may have an actual resistance value that varies by 5% from its nominal value. In automotive applications, tight tolerance levels are often necessary to ensure circuit reliability and performance, especially in critical systems like engine management and safety features.

D. Temperature Coefficient

The temperature coefficient of a resistor indicates how its resistance changes with temperature. In automotive environments, where temperatures can fluctuate significantly, understanding the temperature coefficient is crucial. Resistors with low temperature coefficients are preferred in automotive applications, as they maintain stable performance across a wide range of temperatures.

E. Size and Form Factor

The physical dimensions of automotive resistors are important for integration into vehicle designs. Space constraints in modern vehicles require resistors to be compact and lightweight. Common sizes and shapes include surface-mount resistors and through-hole resistors, each suited for different applications and mounting techniques.

IV. Material Composition

A. Common Materials Used in Automotive Resistors

The material composition of automotive resistors significantly impacts their performance and durability. Common materials include:

Carbon Composition: These resistors are made from a mixture of carbon and ceramic materials. They are cost-effective but may have higher noise levels and lower stability compared to other types.

Metal Film: Metal film resistors offer better stability and lower noise levels. They are often used in precision applications where accuracy is critical.

Wire Wound: Wire wound resistors are constructed by winding a metal wire around a core. They can handle high power ratings and are often used in applications requiring high precision and stability.

B. Impact of Material Choice on Performance and Durability

The choice of material affects not only the electrical performance of the resistor but also its durability in harsh automotive environments. For instance, metal film resistors are more resistant to temperature fluctuations and mechanical stress, making them suitable for critical applications in vehicles.

V. Environmental Considerations

A. Resistance to Vibration and Shock

Automotive components are subjected to constant vibration and shock due to road conditions. Resistors must be designed to withstand these forces to ensure reliability. Features such as robust mounting and encapsulation can enhance the durability of resistors in automotive applications.

B. Temperature Resistance

Automotive resistors must operate effectively across a wide range of temperatures, from extreme cold to high heat. Understanding the operating temperature ranges and ensuring thermal stability is crucial for maintaining performance and preventing failure.

C. Moisture and Corrosion Resistance

Vehicles are exposed to moisture, dirt, and corrosive substances, making it essential for resistors to have adequate protection. Coatings and treatments, such as conformal coatings, can enhance moisture and corrosion resistance, ensuring long-term reliability in automotive environments.

VI. Applications of Automotive Resistors

A. Engine Management Systems

In engine management systems, resistors play a vital role in fuel injection and ignition systems. They help regulate the signals sent to various sensors and actuators, ensuring optimal engine performance and efficiency.

B. Electrical Systems

Automotive electrical systems rely on resistors for various functions, including lighting, infotainment, and power distribution. Resistors help manage current flow and protect sensitive components from damage.

C. Safety Systems

In safety systems, such as airbags and anti-lock braking systems, resistors are critical for ensuring reliable operation. They help monitor and control signals, contributing to the overall safety of the vehicle.

D. Comfort Features

Resistors are also used in comfort features, such as climate control and seat adjustments. They enable precise control over temperature settings and seat positioning, enhancing the overall driving experience.

VII. Trends and Innovations in Automotive Resistors

A. Advances in Materials and Technology

The automotive industry is witnessing advancements in materials and technology, leading to the development of more efficient and reliable resistors. Innovations such as thin-film technology and advanced ceramics are improving performance and durability.

B. Integration with Smart Automotive Systems

As vehicles become more connected and automated, resistors are being integrated into smart automotive systems. This integration allows for enhanced functionality, such as adaptive lighting and advanced driver-assistance systems (ADAS).

C. Future Directions in Automotive Resistor Design

The future of automotive resistor design will likely focus on miniaturization, improved thermal management, and enhanced environmental resistance. As electric and hybrid vehicles become more prevalent, resistors will need to adapt to new challenges and requirements.

VIII. Conclusion

Automotive resistors are critical components that ensure the proper functioning of various systems within a vehicle. Understanding their types, key features, material composition, and applications is essential for anyone involved in automotive design and engineering. As technology continues to evolve, the role of resistors in automotive applications will only become more significant, driving innovation and enhancing vehicle performance, safety, and comfort.

IX. References

For further reading and research on automotive resistors, consider exploring the following sources:

1. "Automotive Electronics Handbook" by Ronald K. Jurgen

2. "Fundamentals of Automotive Technology" by Mark Schnubel

3. Industry publications and technical papers on automotive resistor technology and applications.