How to Choose Spot Fuse Resistors

I. Introduction

In the world of electronics, ensuring the safety and reliability of circuits is paramount. One critical component that plays a significant role in circuit protection is the spot fuse resistor. This article will delve into the intricacies of spot fuse resistors, their importance, and how to choose the right one for your specific application.

A. Definition of Spot Fuse Resistors

Spot fuse resistors are specialized components that combine the functions of a resistor and a fuse. They are designed to limit current flow in a circuit while also providing overcurrent protection. When the current exceeds a predetermined threshold, the fuse element within the resistor will blow, effectively interrupting the circuit and preventing damage to other components.

B. Importance of Choosing the Right Spot Fuse Resistor

Selecting the appropriate spot fuse resistor is crucial for the longevity and safety of electronic devices. An incorrect choice can lead to circuit failure, component damage, or even safety hazards. Therefore, understanding the specifications and characteristics of these components is essential for any engineer or designer.

C. Overview of the Article

This article will guide you through the process of choosing spot fuse resistors, covering their types, key specifications, environmental considerations, performance characteristics, compliance standards, sourcing options, and practical tips for selection.

II. Understanding Spot Fuse Resistors

A. What are Spot Fuse Resistors?

1. Function and Purpose

Spot fuse resistors serve dual purposes: they limit current flow and protect circuits from overcurrent conditions. By integrating these functions, they simplify circuit design and enhance reliability.

2. Applications in Electronics

These components are widely used in various applications, including power supplies, automotive electronics, consumer devices, and industrial equipment. Their ability to protect sensitive components makes them invaluable in modern electronics.

B. Types of Spot Fuse Resistors

1. Surface Mount Fuse Resistors

Surface mount fuse resistors are designed for automated assembly processes and are ideal for compact circuit designs. They offer low profile and high reliability, making them suitable for high-density applications.

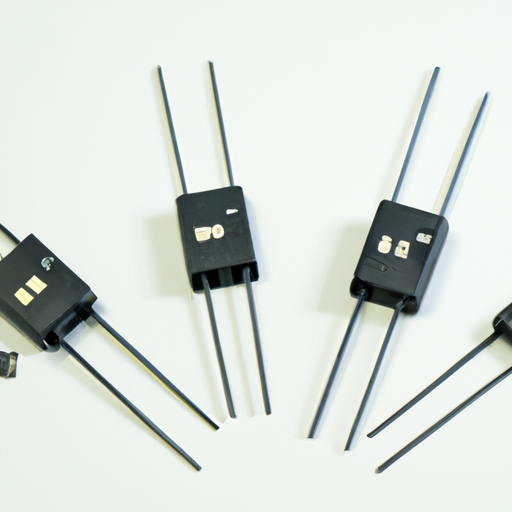

2. Through-Hole Fuse Resistors

Through-hole fuse resistors are mounted by inserting leads into holes on a printed circuit board (PCB). They are often used in applications where higher power ratings are required and provide robust mechanical support.

3. Specialty Fuse Resistors

Specialty fuse resistors are tailored for specific applications, such as high-temperature environments or unique circuit requirements. These components may have enhanced features like increased moisture resistance or specific voltage ratings.

III. Key Specifications to Consider

A. Resistance Value

1. Importance of Resistance in Circuit Design

The resistance value of a fuse resistor is critical in determining how much current will flow through the circuit under normal conditions. Selecting the correct resistance ensures that the circuit operates efficiently without exceeding safe current levels.

2. How to Determine the Required Resistance

To determine the required resistance, consider the circuit's voltage and current specifications. Ohm's Law (V = IR) can be used to calculate the necessary resistance value based on the desired current flow.

B. Power Rating

1. Definition and Importance

The power rating indicates the maximum amount of power the resistor can dissipate without failing. It is essential to choose a fuse resistor with a power rating that exceeds the expected power dissipation in the circuit.

2. Calculating Power Requirements

Power can be calculated using the formula P = I²R, where P is power, I is current, and R is resistance. This calculation helps ensure that the selected fuse resistor can handle the expected load.

C. Temperature Coefficient

1. Explanation of Temperature Coefficient

The temperature coefficient indicates how much the resistance value changes with temperature. A low temperature coefficient is desirable for applications requiring stable performance across varying temperatures.

2. Impact on Performance

A high temperature coefficient can lead to significant changes in resistance, affecting circuit performance and reliability. Therefore, selecting a fuse resistor with an appropriate temperature coefficient is crucial.

D. Voltage Rating

1. Understanding Voltage Ratings

The voltage rating specifies the maximum voltage the fuse resistor can handle without breaking down. Exceeding this rating can lead to catastrophic failure.

2. Importance in Circuit Safety

Choosing a fuse resistor with an adequate voltage rating is essential for ensuring circuit safety and preventing damage to other components.

IV. Environmental Considerations

A. Operating Temperature Range

Consider the operating temperature range of the application. Ensure that the selected fuse resistor can function effectively within the expected temperature limits.

B. Humidity and Moisture Resistance

In environments with high humidity or moisture, selecting a fuse resistor with moisture resistance is vital to prevent corrosion and failure.

C. Chemical Resistance

For applications exposed to chemicals, choose fuse resistors that offer chemical resistance to ensure longevity and reliability.

D. Mechanical Stress and Vibration Resistance

In applications subject to mechanical stress or vibration, selecting robust fuse resistors that can withstand these conditions is essential for maintaining performance.

V. Performance Characteristics

A. Response Time

The response time of a fuse resistor is critical in applications where rapid overcurrent protection is necessary. A faster response time can prevent damage to sensitive components.

B. Reliability and Longevity

Reliability is a key factor in the selection of fuse resistors. Look for components with a proven track record of longevity and consistent performance.

C. Failure Modes

1. Open Circuit Failure

In an open circuit failure, the fuse element blows, interrupting the current flow. This is the desired failure mode for overcurrent protection.

2. Short Circuit Failure

In a short circuit failure, the fuse resistor may not blow as intended, leading to potential damage to the circuit. Understanding the failure modes helps in selecting the right component for your application.

VI. Compliance and Standards

A. Industry Standards for Fuse Resistors

1. UL, IEC, and RoHS Compliance

Ensure that the selected fuse resistors comply with industry standards such as UL (Underwriters Laboratories), IEC (International Electrotechnical Commission), and RoHS (Restriction of Hazardous Substances).

B. Importance of Certification

Certification ensures that the components meet safety and performance standards, providing peace of mind for designers and manufacturers.

C. How to Verify Compliance

Check the manufacturer's documentation and certifications to verify compliance with relevant standards.

VII. Sourcing and Manufacturer Considerations

A. Reputable Manufacturers

Choose fuse resistors from reputable manufacturers known for quality and reliability. Researching manufacturer backgrounds can help ensure you select high-quality components.

B. Evaluating Supplier Quality

Evaluate suppliers based on their quality control processes, customer reviews, and industry reputation. A reliable supplier can significantly impact the overall quality of your project.

C. Cost vs. Quality Trade-offs

While cost is an important factor, prioritize quality over price. Investing in high-quality fuse resistors can save money in the long run by reducing failures and improving reliability.

VIII. Practical Tips for Selection

A. Application-Specific Considerations

Consider the specific requirements of your application when selecting fuse resistors. Different applications may have unique needs that influence your choice.

B. Prototyping and Testing

Before finalizing your selection, prototype and test the chosen fuse resistors in your circuit. This step can help identify any potential issues and ensure compatibility.

C. Consulting with Experts

When in doubt, consult with experts or experienced colleagues. Their insights can provide valuable guidance in selecting the right components for your project.

IX. Conclusion

A. Recap of Key Points

Choosing the right spot fuse resistor involves understanding their function, specifications, environmental considerations, and compliance standards. By carefully evaluating these factors, you can ensure the safety and reliability of your electronic circuits.

B. Final Thoughts on Choosing Spot Fuse Resistors

The selection process may seem daunting, but thorough research and consideration of your specific application can lead to informed decisions.

C. Encouragement to Conduct Thorough Research

Take the time to explore various options, consult with experts, and test components to find the best fit for your needs. The right spot fuse resistor can make all the difference in the performance and safety of your electronic designs.

X. References

A. Suggested Reading and Resources

- "Electronic Components: A Complete Reference for Engineers and Technicians" by John Doe

- "Understanding Resistors and Their Applications" by Jane Smith

B. Industry Publications and Standards Documents

- UL Standards for Fuse Resistors

- IEC Standards for Electronic Components

- RoHS Compliance Guidelines

By following this comprehensive guide, you can confidently choose the right spot fuse resistors for your electronic projects, ensuring both performance and safety.