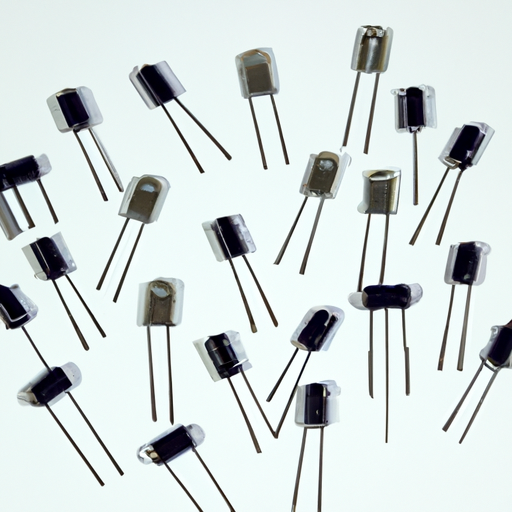

Popular Models of Common Varistors

I. Introduction

A. Definition of Varistors

Varistors, or voltage-dependent resistors, are essential components in electrical circuits, designed to protect sensitive electronic devices from voltage spikes. They function by exhibiting a non-linear resistance that decreases as the voltage across them increases. This unique property allows varistors to clamp excessive voltage, thereby preventing damage to connected components. Their ability to absorb and dissipate energy makes them invaluable in various applications, from consumer electronics to industrial machinery.

B. Purpose of the Article

This article aims to provide an overview of popular varistor models, highlighting their specifications and applications. Understanding these models is crucial for engineers and hobbyists alike, as they play a significant role in safeguarding electronic devices from transient voltage surges.

II. Understanding Varistors

A. How Varistors Work

Varistors operate on the principle of voltage clamping. When the voltage across a varistor exceeds a certain threshold, its resistance drops dramatically, allowing it to conduct excess current and divert it away from sensitive components. This non-linear resistance characteristic is what makes varistors effective in surge protection.

B. Types of Varistors

1. **Metal Oxide Varistors (MOVs)**: The most common type, MOVs are made from a ceramic material that contains zinc oxide. They are widely used due to their high energy absorption capacity and fast response times.

2. **Silicon Carbide Varistors (SiC)**: These varistors are known for their high-temperature stability and robustness. They are often used in high-power applications where reliability is critical.

3. **Zener Diodes as Varistors**: While not traditional varistors, Zener diodes can also provide voltage clamping. They are often used in low-power applications where precise voltage regulation is required.

III. Key Specifications of Varistors

A. Voltage Rating

1. **Maximum Continuous Voltage**: This is the highest voltage that a varistor can withstand without conducting. Exceeding this voltage can lead to failure.

2. **Clamping Voltage**: This is the voltage level at which the varistor begins to conduct significantly. It is crucial for determining how effectively a varistor can protect against surges.

B. Energy Rating

1. **Energy Absorption Capacity**: This specification indicates how much energy a varistor can absorb during a surge event without being damaged.

2. **Surge Current Handling**: This refers to the maximum current that a varistor can handle during a surge. It is essential for ensuring that the varistor can protect the circuit under extreme conditions.

C. Response Time

The response time of a varistor is critical in surge protection applications. A fast response time ensures that the varistor can react quickly to voltage spikes, minimizing the risk of damage to connected devices.

D. Temperature Coefficient

The temperature coefficient indicates how the performance of a varistor changes with temperature. Understanding this characteristic is vital for applications in environments with varying temperatures.

IV. Popular Varistor Models

A. MOV Models

1. **Vishay V150LA20AP**

- **Specifications**: This MOV has a maximum continuous voltage of 150V and a clamping voltage of 320V. It can absorb up to 1500J of energy.

- **Applications**: Commonly used in power supplies and consumer electronics for surge protection.

2. **Littelfuse 14K275**

- **Specifications**: With a maximum continuous voltage of 275V and a clamping voltage of 500V, this model can handle surge currents up to 14kA.

- **Applications**: Ideal for industrial equipment and telecommunications.

3. **Panasonic ERZ-V10D**

- **Specifications**: This varistor has a maximum continuous voltage of 10V and a clamping voltage of 20V, making it suitable for low-voltage applications.

- **Applications**: Often used in automotive electronics and low-power devices.

B. SiC Varistors

1. **Cree C3M Series**

- **Specifications**: Known for its high-temperature stability, this series can handle voltages up to 1200V and surge currents of 100A.

- **Applications**: Used in high-power applications, including renewable energy systems.

2. **ROHM RGS Series**

- **Specifications**: This series features a maximum voltage rating of 600V and is designed for high-frequency applications.

- **Applications**: Commonly found in telecommunications and industrial automation.

C. Zener Diode Varistors

1. **Bourns 1N5220B**

- **Specifications**: This Zener diode has a reverse voltage of 24V and can handle up to 1W of power.

- **Applications**: Suitable for low-power applications requiring voltage regulation.

2. **ON Semiconductor 1N4148**

- **Specifications**: With a maximum reverse voltage of 100V, this diode is known for its fast switching speed.

- **Applications**: Often used in signal processing and low-voltage circuits.

V. Applications of Varistors

A. Consumer Electronics

Varistors are widely used in consumer electronics to protect devices such as televisions, computers, and home appliances from voltage spikes caused by lightning strikes or power surges.

B. Industrial Equipment

In industrial settings, varistors safeguard manufacturing machinery and control systems from electrical transients, ensuring operational reliability and reducing downtime.

C. Telecommunications

Varistors play a crucial role in telecommunications equipment, protecting sensitive components from voltage fluctuations that can disrupt communication signals.

D. Automotive

In the automotive industry, varistors are used to protect electronic control units (ECUs) and other sensitive components from voltage spikes, ensuring the reliability of modern vehicles.

VI. Advantages and Disadvantages of Varistors

A. Advantages

1. **Cost-effectiveness**: Varistors are relatively inexpensive compared to other surge protection devices, making them a popular choice for many applications.

2. **Compact Size**: Their small form factor allows for easy integration into various electronic devices without taking up much space.

3. **High Energy Absorption**: Varistors can absorb significant amounts of energy, providing robust protection against voltage surges.

B. Disadvantages

1. **Aging and Degradation Over Time**: Varistors can degrade with repeated surge events, leading to reduced effectiveness and eventual failure.

2. **Limited Response Time in Certain Conditions**: While generally fast, some varistors may have slower response times under specific conditions, potentially allowing damaging surges to pass through.

VII. Conclusion

A. Summary of Key Points

Varistors are critical components in protecting electronic devices from voltage surges. Understanding the different types, specifications, and popular models can help engineers and hobbyists select the right varistor for their applications. From consumer electronics to industrial machinery, varistors play a vital role in ensuring the reliability and longevity of electronic systems.

B. Future Trends in Varistor Technology

As technology advances, we can expect innovations in varistor materials and designs. The increasing demand for reliable surge protection in an ever-connected world will drive the development of more efficient and durable varistors, ensuring that electronic devices remain safe from voltage spikes.

VIII. References

- Manufacturer datasheets for specific varistor models

- Technical articles on varistor technology

- Industry standards for surge protection devices

This comprehensive overview of popular varistor models highlights their importance in various applications, providing valuable insights for anyone involved in electronics design and protection.