What are the Product Characteristics of Capacitor Films?

I. Introduction

Capacitor films are essential components in the world of electronics, playing a crucial role in energy storage and signal processing. These films are thin layers of dielectric material that serve as the insulating medium between conductive plates in capacitors. Their unique properties make them indispensable in various applications, from consumer electronics to industrial machinery. This blog post aims to explore the product characteristics of capacitor films, shedding light on their types, key properties, manufacturing processes, applications, advantages, disadvantages, and future trends.

II. Overview of Capacitor Films

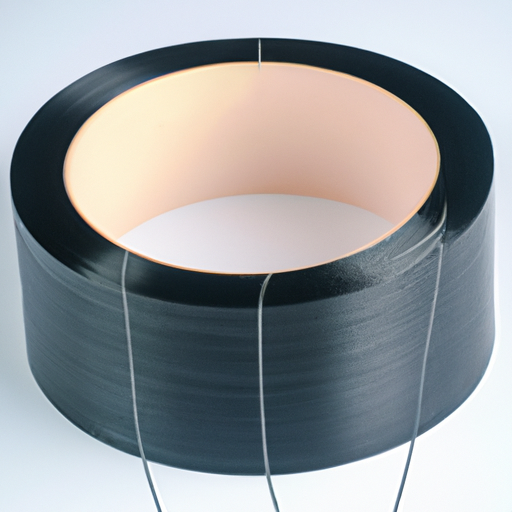

A. What are Capacitor Films?

Capacitor films are thin layers of dielectric materials used in capacitors to store electrical energy. They function by accumulating charge on conductive plates separated by the dielectric film, allowing for energy storage and release when needed. The efficiency and performance of a capacitor largely depend on the characteristics of the film used.

1. Basic Functionality

The primary function of capacitor films is to provide a medium for charge storage. When voltage is applied across the plates, an electric field is created, allowing the capacitor to store energy. The dielectric material's properties significantly influence the capacitor's performance, including its capacitance, voltage rating, and overall efficiency.

2. Types of Capacitor Films

Capacitor films can be made from various materials, each offering distinct characteristics and applications. The most common types include polyester (PET), polypropylene (PP), and polycarbonate (PC) films, among others.

B. Historical Development

The development of capacitor technology has evolved significantly over the years. From the early days of capacitors made from glass and paper to modern films made from advanced polymers, the journey has been marked by key milestones that have enhanced performance and reliability.

1. Evolution of Capacitor Technology

The first capacitors were simple devices that used rudimentary materials. As technology advanced, the introduction of synthetic polymers revolutionized capacitor design, leading to the development of film capacitors that are more efficient and reliable.

2. Key Milestones in Film Capacitor Development

The introduction of polyester films in the 1960s marked a significant advancement in capacitor technology. This was followed by the development of polypropylene films, which offered improved performance characteristics. Today, ongoing research continues to push the boundaries of capacitor film technology.

III. Types of Capacitor Films

A. Polyester (PET) Films

1. Characteristics

Polyester films are known for their excellent dielectric properties, high insulation resistance, and good thermal stability. They typically have a dielectric constant ranging from 2.5 to 3.0 and a high voltage rating.

2. Applications

PET films are widely used in consumer electronics, such as audio equipment, power supplies, and lighting applications, due to their reliability and cost-effectiveness.

B. Polypropylene (PP) Films

1. Characteristics

Polypropylene films offer superior electrical properties, including low dissipation factors and high capacitance stability over a wide temperature range. They are also resistant to moisture and chemicals.

2. Applications

PP films are commonly used in high-frequency applications, such as RF circuits, as well as in power electronics and automotive applications.

C. Polycarbonate (PC) Films

1. Characteristics

Polycarbonate films are known for their high impact resistance and excellent thermal stability. They have a higher dielectric constant compared to PET and PP films, making them suitable for specific applications.

2. Applications

PC films are often used in applications requiring high reliability, such as aerospace and military electronics.

D. Other Types of Films

1. Polyphenylene Sulfide (PPS)

PPS films are known for their high thermal stability and chemical resistance, making them suitable for harsh environments.

2. Polystyrene (PS)

Polystyrene films are used in applications where low capacitance values are acceptable, such as in coupling and bypass capacitors.

IV. Key Product Characteristics of Capacitor Films

A. Dielectric Properties

1. Dielectric Constant

The dielectric constant is a measure of a material's ability to store electrical energy in an electric field. Higher dielectric constants indicate better energy storage capabilities.

2. Dissipation Factor

The dissipation factor measures the energy loss in a capacitor due to dielectric heating. Lower dissipation factors indicate higher efficiency.

3. Voltage Rating

The voltage rating indicates the maximum voltage a capacitor can handle without breaking down. It is crucial for ensuring the reliability of the capacitor in its application.

B. Temperature Stability

1. Operating Temperature Range

Capacitor films must operate effectively within a specified temperature range. Materials with high thermal stability can function in extreme conditions without degrading.

2. Thermal Aging

Thermal aging refers to the degradation of dielectric properties over time due to prolonged exposure to high temperatures. High-quality films exhibit minimal thermal aging.

C. Mechanical Properties

1. Tensile Strength

Tensile strength measures a material's resistance to being pulled apart. High tensile strength is essential for maintaining structural integrity during operation.

2. Flexibility and Bend Radius

Flexibility is crucial for applications requiring tight spaces or complex shapes. A smaller bend radius indicates better flexibility.

D. Electrical Characteristics

1. Capacitance Value

The capacitance value indicates the amount of charge a capacitor can store. It is a critical parameter for determining the capacitor's suitability for specific applications.

2. Tolerance Levels

Tolerance levels indicate the acceptable variation in capacitance values. Tight tolerances are essential for precision applications.

3. Leakage Current

Leakage current refers to the small amount of current that flows through the dielectric material. Low leakage current is desirable for efficient energy storage.

E. Environmental Resistance

1. Moisture Resistance

Capacitor films must resist moisture to prevent degradation and ensure long-term reliability.

2. Chemical Resistance

Chemical resistance is essential for applications in harsh environments where exposure to corrosive substances may occur.

3. UV Stability

UV stability is crucial for outdoor applications where exposure to sunlight can degrade materials over time.

V. Manufacturing Processes

A. Film Production Techniques

1. Extrusion

Extrusion is a common method for producing capacitor films, where raw materials are melted and formed into thin sheets.

2. Coating

Coating techniques are used to apply dielectric materials onto substrates, enhancing their electrical properties.

B. Capacitor Assembly

1. Layering Techniques

Layering techniques involve stacking multiple layers of dielectric films to achieve desired capacitance values.

2. Connection Methods

Connection methods ensure reliable electrical connections between the capacitor's plates and external circuits.

VI. Applications of Capacitor Films

Capacitor films find applications across various industries, including:

A. Consumer Electronics

Used in devices like smartphones, televisions, and audio equipment for energy storage and signal processing.

B. Industrial Equipment

Essential in machinery for power management and control systems.

C. Automotive Applications

Used in electric vehicles and advanced driver-assistance systems (ADAS) for energy storage and filtering.

D. Renewable Energy Systems

Capacitor films play a vital role in solar inverters and wind turbine systems for energy conversion and storage.

E. Telecommunications

Used in communication devices for signal filtering and energy storage.

VII. Advantages and Disadvantages of Capacitor Films

A. Advantages

1. High Efficiency

Capacitor films offer high energy efficiency, making them suitable for various applications.

2. Compact Size

Their thin profile allows for compact designs in electronic devices.

3. Versatility

Capacitor films can be tailored for specific applications, providing flexibility in design.

B. Disadvantages

1. Cost Considerations

High-quality capacitor films can be more expensive than traditional capacitor materials.

2. Limited Voltage Ratings

Some capacitor films may have lower voltage ratings, limiting their use in high-voltage applications.

VIII. Future Trends in Capacitor Film Technology

A. Innovations in Materials

Research is ongoing to develop new materials that enhance the performance and reliability of capacitor films.

B. Advances in Manufacturing Techniques

Improvements in manufacturing processes are expected to reduce costs and increase production efficiency.

C. Emerging Applications

As technology evolves, new applications for capacitor films are likely to emerge, particularly in renewable energy and electric vehicles.

IX. Conclusion

In summary, capacitor films are critical components in modern electronics, offering a range of characteristics that make them suitable for various applications. Their dielectric properties, temperature stability, mechanical strength, and environmental resistance are key factors that determine their performance. As technology continues to advance, capacitor films will play an increasingly important role in shaping the future of electronic devices and systems.

X. References

- Academic Journals

- Industry Reports

- Manufacturer Specifications

This blog post provides a comprehensive overview of the product characteristics of capacitor films, highlighting their importance in the electronics industry and their potential for future innovations.